Thanks for the advice linearone. I've seen ferrites mentioned a lot but was not quite sure why/when/where they are used. The antenna feedpoint is about 33 feet up a pole so this will have to wait until spring and the snow/ice is off the roof and I can take the antenna down. I am hoping a tilting tower will be replacing it so making this kind of fix/change in the future will be no big deal.Clamp some ferrites on the coax under the antenna right at the feedpoint. 3-7 should do it. I never had lunch with the air wound coax coil balun. You could also try a 1:1 balun but that costs money. Ferrite is cheaper.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

-

You can now help support WorldwideDX when you shop on Amazon at no additional cost to you! Simply follow this Shop on Amazon link first and a portion of any purchase is sent to WorldwideDX to help with site costs.

Carl Built

- Thread starter Staybolt

- Start date

if you dont have any issues due to common mode currents, dont waste your time and money on a transmission line choke, its completely unnecessary. im willing to bet you dontThanks for the advice linearone. I've seen ferrites mentioned a lot but was not quite sure why/when/where they are used. The antenna feedpoint is about 33 feet up a pole so this will have to wait until spring and the snow/ice is off the roof and I can take the antenna down. I am hoping a tilting tower will be replacing it so making this kind of fix/change in the future will be no big deal.

Bonding all site grounds together is the correct way to do it, ideally the coax would enter the house at the same point as the electric service.Initially I did have the antenna and mast it is mounted on going to its own ground rod right at the base of the mast but then my understanding became that this was possibly causing a ground loop or some other issue/concern and that I needed to have this second ground rod bonded to the main house ground rod that is about 20 feet away, which is what I did. Now the ground rod for the antenna/mast is bonded to the main house ground as is the ground strap that leads from the bonding bar (that I have the radio, amp, etc connected to with copper braid in my radio shack aka my office) to the outside ground rod.

So as not to further pollute this Carl Built thread, the gory details of my station setup are in this thread. Like with the amps, there are multiple mistakes/missteps as I am learning the ropes.

It's entirely possible I misunderstood the recommendations on how to configure the grounds.

You can not have to much ground system, the more the better and safer you are from lightning. My base station currently has a ground ring/field consisting of 15 ground rods bonded together with 4ga solid.

Guys , it's a four pill. Its not a 5kw amplifier. If it's given him a problem on his setup, he's got something weird happening. I'm not insulting him, I'm just saying it's a pretty simple setup to diagnose. He's already figured out that it's not the amplifier.

i know right. he said he removed the low pass filter and the problem went away. end of story, problem solved!Guys , it's a four pill. Its not a 5kw amplifier. If it's given him a problem on his setup, he's got something weird happening. I'm not insulting him, I'm just saying it's a pretty simple setup to diagnose. He's already figured out that it's not the amplifier.

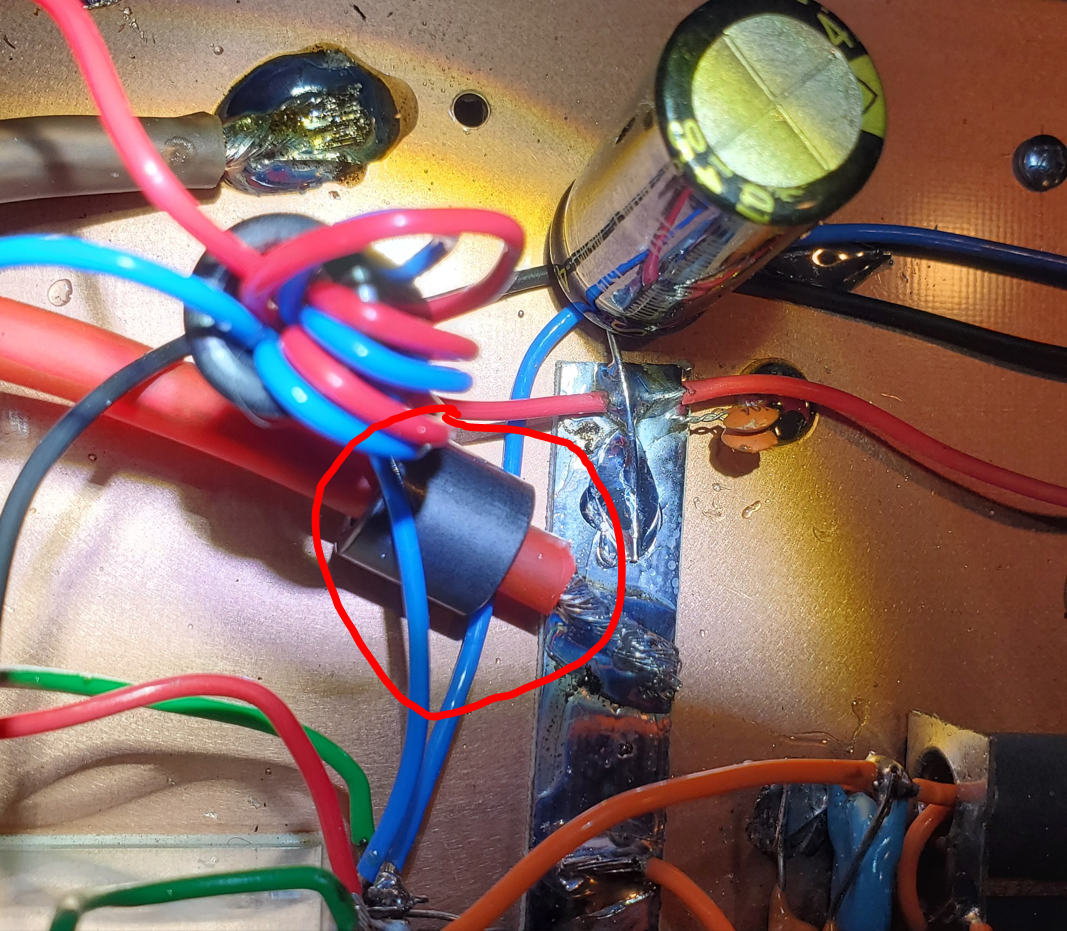

I am in the process of replacing the much-too-short 8 awg power cables on my 200HDC with six foot long 6 awg cables. The outer diameter of the new 6 awg positive cable is 10mm and this is too large to fit inside the ring that the current 8 awg wire goes through right before where it is soldered onto a bar. I assume this ring is important so I want to replace it with the right one that fits this larger OD cable.

Any chance any of you folks know what I should use here?

Any chance any of you folks know what I should use here?

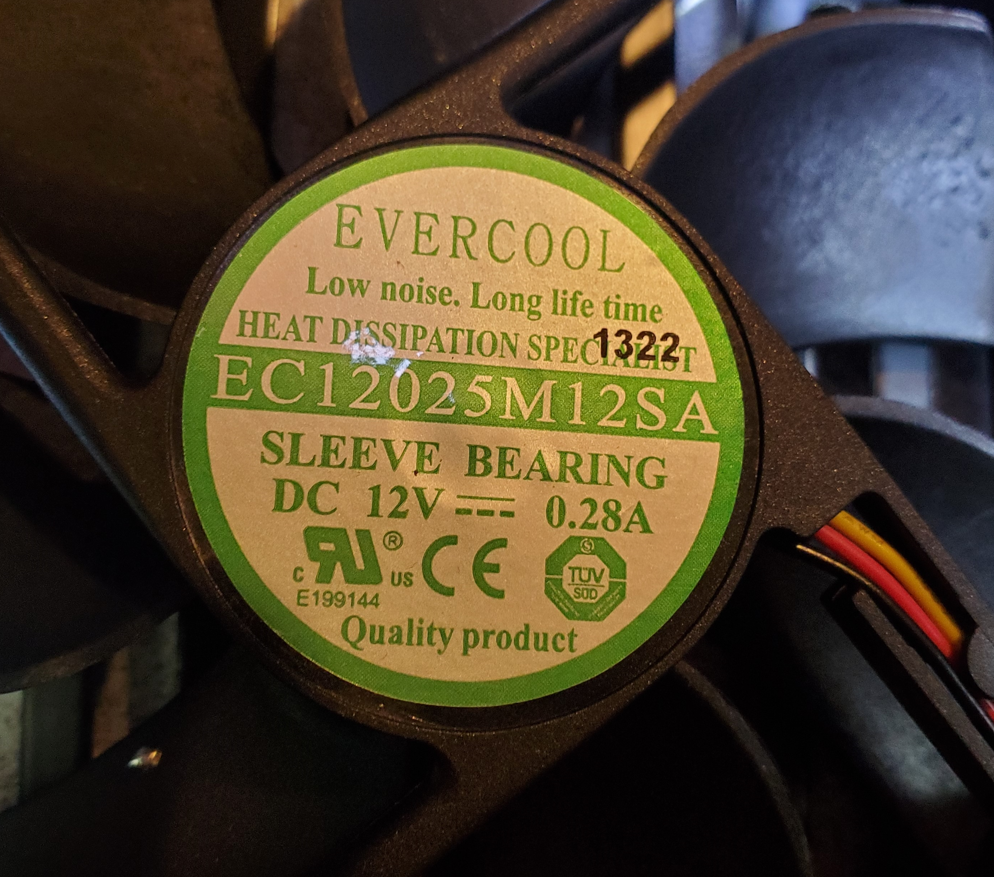

In case anyone is interested/curious, this is the fan that came in my new 200HDC. I'm going to see if I can find a different fan that fits, keeps the amp safely cooled but is a bit less boisterous when doing so. Who knows, this may turn out to be a snipe hunt but I won't know for sure until I look.

its more than likely a type 43 ferrite bead. you can get them in different sizes and different inner diameters. they are called by different names but are bassically the same thing ferrite bead, ferrite ring, ferrite core. just one of many suppliers for an example. https://www.kf7p.com/KF7P/Ferrite_chokes.htmlI am in the process of replacing the much-too-short 8 awg power cables on my 200HDC with six foot long 6 awg cables. The outer diameter of the new 6 awg positive cable is 10mm and this is too large to fit inside the ring that the current 8 awg wire goes through right before where it is soldered onto a bar. I assume this ring is important so I want to replace it with the right one that fits this larger OD cable.

Any chance any of you folks know what I should use here?

View attachment 63157

why not just put like a 2 watt series resistor inline to cut the fan speed down. alot cheaper than a new fan.In case anyone is interested/curious, this is the fan that came in my new 200HDC. I'm going to see if I can find a different fan that fits, keeps the amp safely cooled but is a bit less boisterous when doing so. Who knows, this may turn out to be a snipe hunt but I won't know for sure until I look.

View attachment 63158

Thanks for the info. I will do some digging and see if I can find one that looks like it would be a good fit for the new 10mm 6awg cable.its more than likely a type 43 ferrite bead. you can get them in different sizes and different inner diameters. they are called by different names but are bassically the same thing ferrite bead, ferrite ring, ferrite core. just one of many suppliers for an example. https://www.kf7p.com/KF7P/Ferrite_chokes.html

Mainly because I don't know this type of basic stuff yet. I have a lot to learn.why not just put like a 2 watt series resistor inline to cut the fan speed down. alot cheaper than a new fan.

That bead is there as a choke to help stop RF from getting back into the power supply.

It would not hurt to have a couple.

73

Jeff

It would not hurt to have a couple.

73

Jeff

Another cheap Evercool sleeve bearing fan that should not be mounted horizontally. I have seen the same fan on Fatboy amps too.

It's all good. Think of it like this. In your car the fan for the heat or AC has say 4 speed settings for air flow. All the control does is vary the voltage to the fan. So wide open at 14.xx volts the fan is on hi, by the time you get down to the lowest speed that blower is maybe only getting say 5 volts.Mainly because I don't know this type of basic stuff yet. I have a lot to learn.

So on your fan adding a resistor will slow it down. If you ever blow that fan the other thing you can do is replace it with a 24 volt fan that's the same size. By running that fan at only 13.8 volts it will be very quiet and still move plenty of air. Good luck.

Does the bead have to be inside the case close to the solder point where it is now or will it also work if it is just outside the case? If it is outside the case it looks like it gives me more options for size/length/number of them and also clamp on too instead of just slip on. The clamp-on style looks too big to fit well inside the case plus not too sure if it'd be too hot for it in there.That bead is there as a choke to help stop RF from getting back into the power supply.

It would not hurt to have a couple.

73

Jeff