Back in 2012 late year I was working on a TS 830. One of my favorite piece of test gear was my SM-220. Really helps in making sure the transmitter is linier. I really loved that thing!

I left the shop for lunch and returned 30 minutes later to find the shop full of smoke. After a few minutes of searching the source of the smoke was the SM 220. After a quick tear down I found that one of the high voltage caps had failed. Bad part was this shorted the high voltage (500 V) from the transformer to ground. The put the transformer into meltdown.

And the .5 amp fuse did not blow. Well not until the transformer completely fused every winding. :headbang

The transformer is 120 volt primary.

Secondary's are:

6.3 volt @ 0.3 A

15 volt with center tap @ 0.12 A

150 volt @ 0.1 A

500 volt @ 6 MA

After searching the web for a year I come up with no replacements. Did talk with several companies on re-winding or building this little transformer. To the tune of 150 bucks but they say it will not be a direct replacement and may not fit.

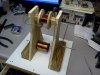

Today I thinking about mounting several transformers in a box. Hoping to get all the voltages I need to bring this piece back to life. I will install a fuse on both sides of the mains input. I feel like if it had this to start with the transformer would has never melted.

I really miss my SM-220

I left the shop for lunch and returned 30 minutes later to find the shop full of smoke. After a few minutes of searching the source of the smoke was the SM 220. After a quick tear down I found that one of the high voltage caps had failed. Bad part was this shorted the high voltage (500 V) from the transformer to ground. The put the transformer into meltdown.

And the .5 amp fuse did not blow. Well not until the transformer completely fused every winding. :headbang

The transformer is 120 volt primary.

Secondary's are:

6.3 volt @ 0.3 A

15 volt with center tap @ 0.12 A

150 volt @ 0.1 A

500 volt @ 6 MA

After searching the web for a year I come up with no replacements. Did talk with several companies on re-winding or building this little transformer. To the tune of 150 bucks but they say it will not be a direct replacement and may not fit.

Today I thinking about mounting several transformers in a box. Hoping to get all the voltages I need to bring this piece back to life. I will install a fuse on both sides of the mains input. I feel like if it had this to start with the transformer would has never melted.

I really miss my SM-220