-

You can now help support WorldwideDX when you shop on Amazon at no additional cost to you! Simply follow this Shop on Amazon link first and a portion of any purchase is sent to WorldwideDX to help with site costs.

-

The Feb 2025 Radioddity Giveaway Results are In! Click Here to see who won!

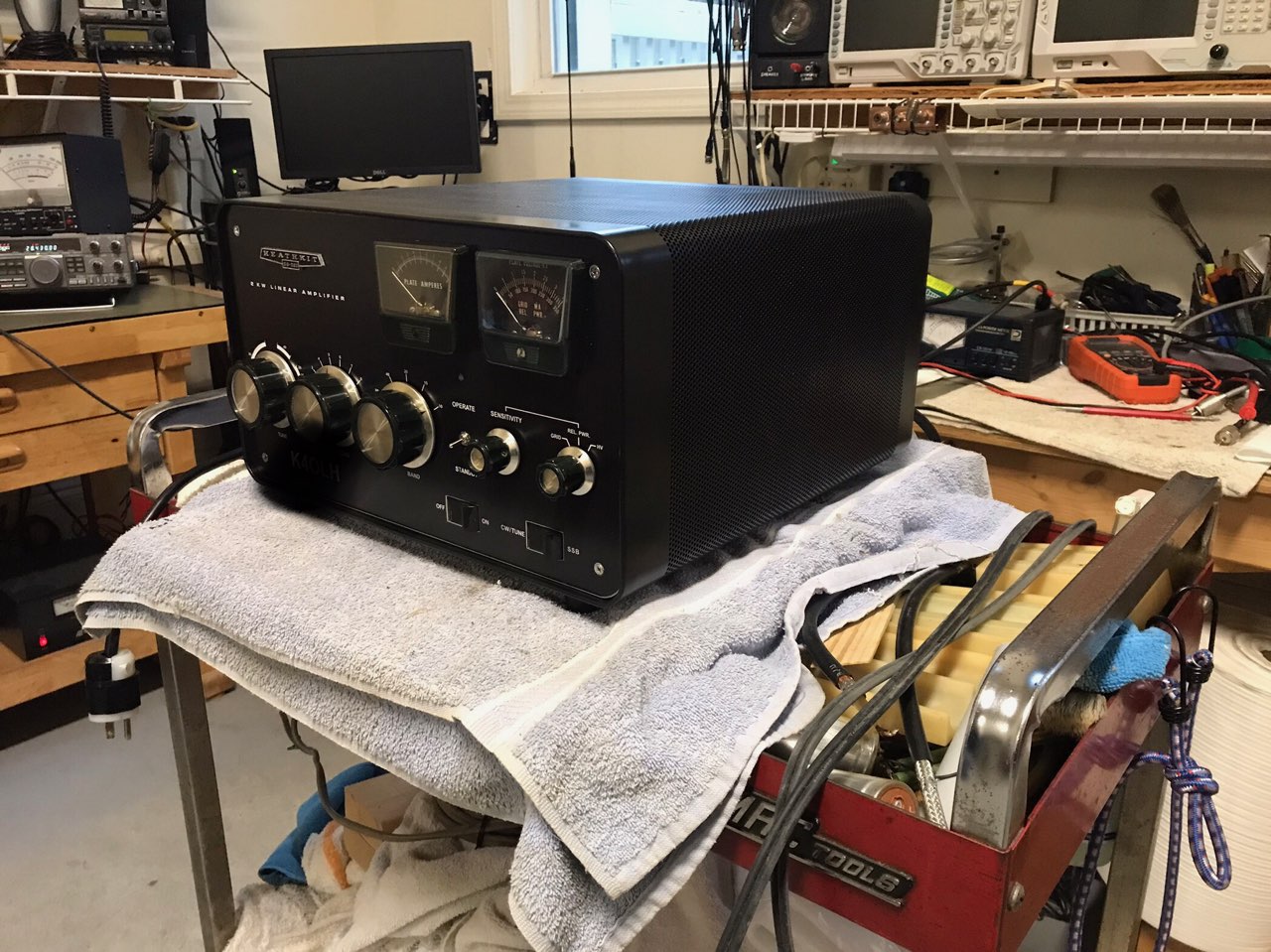

An SB-220 needing lots of attention

- Thread starter Dmans

- Start date

To continue..........

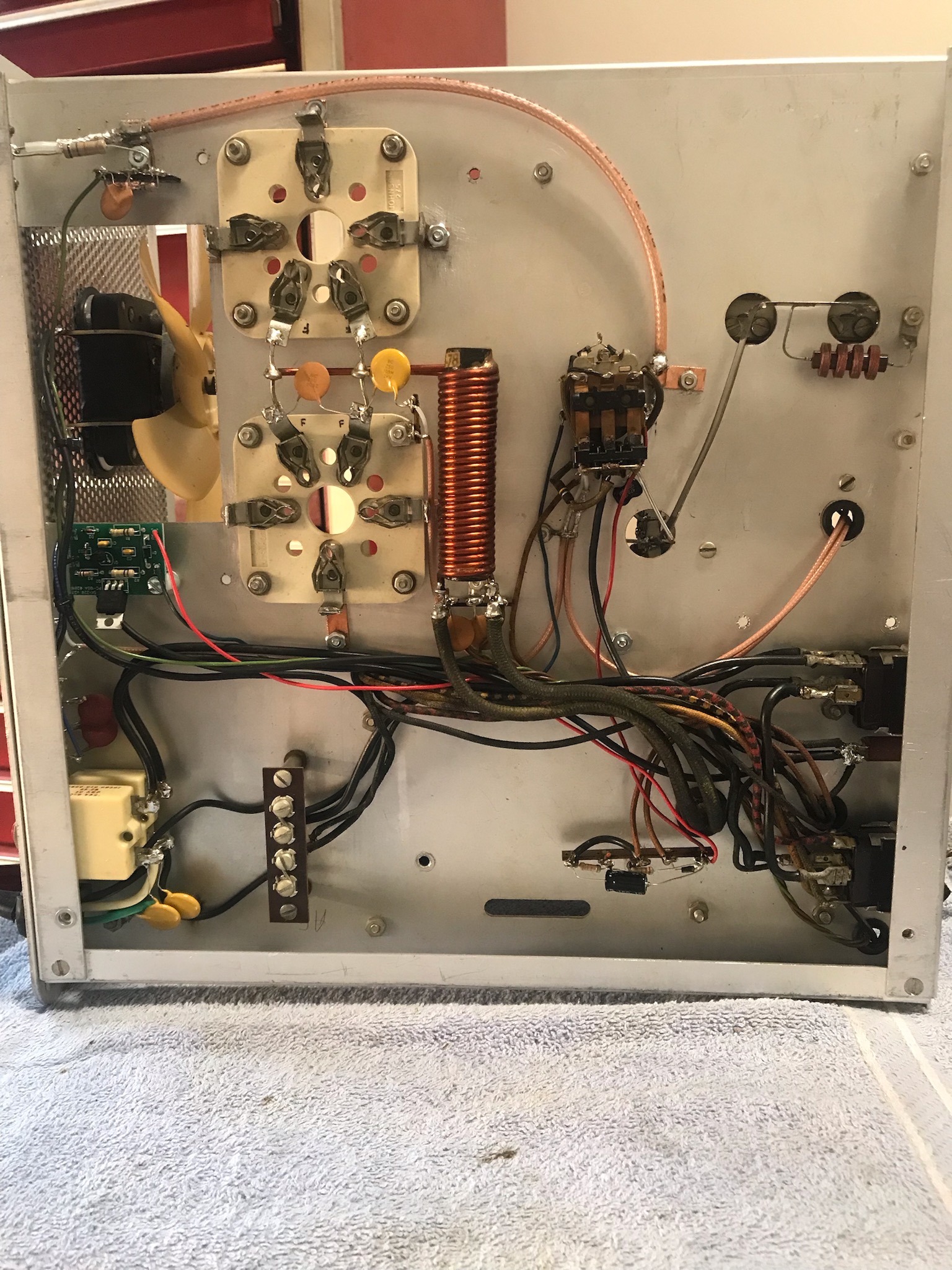

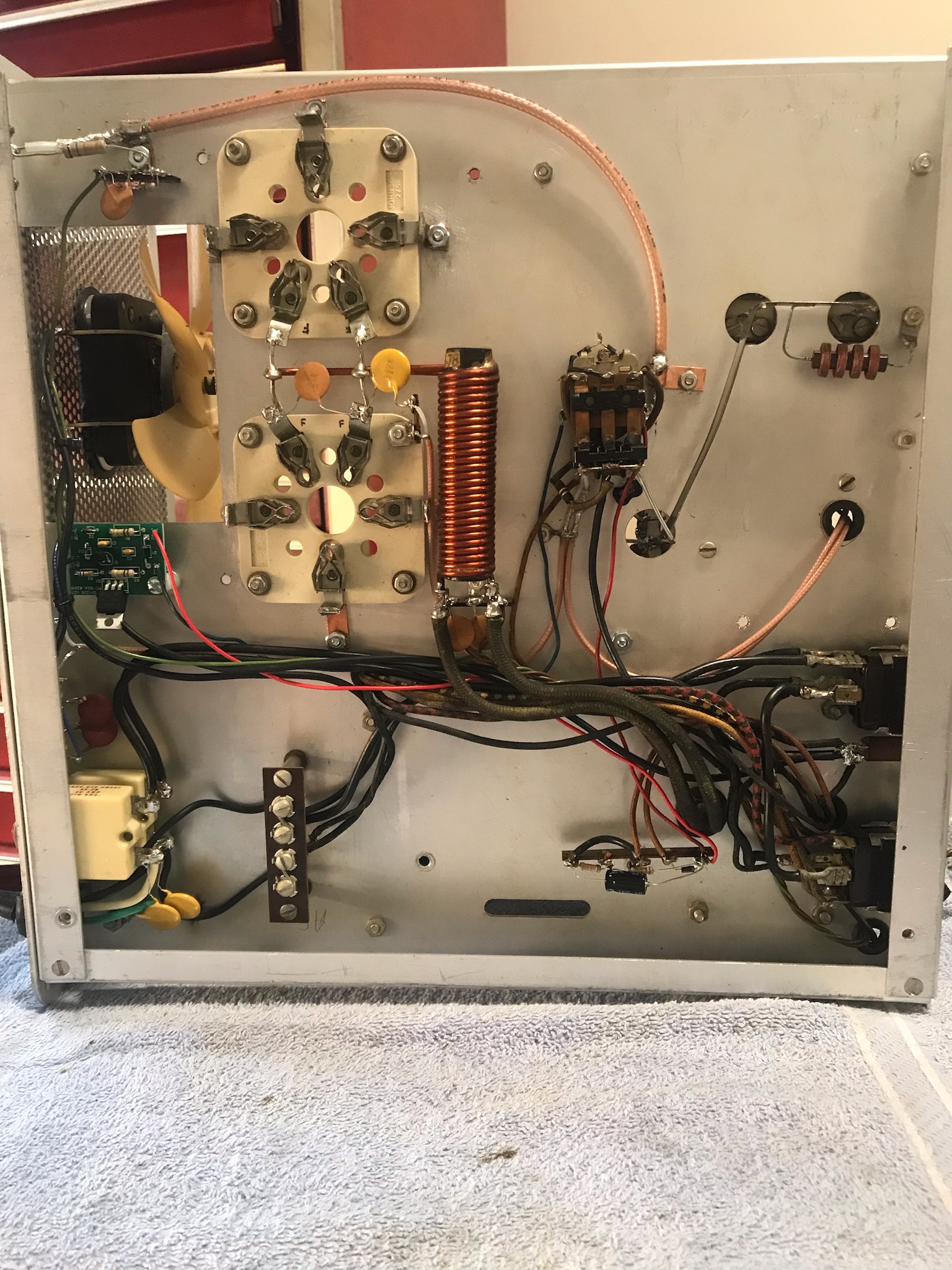

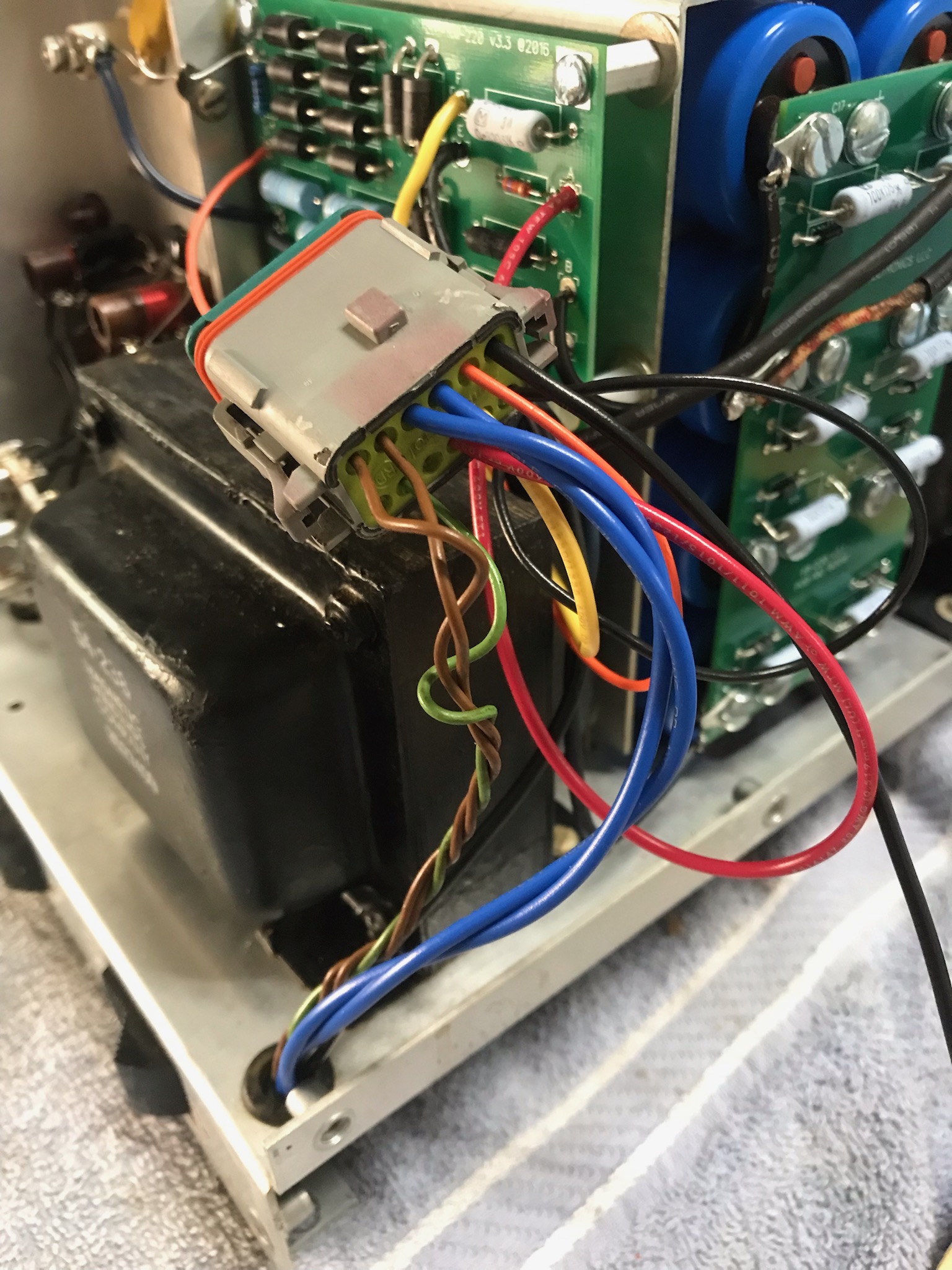

The internal coax runs were replaced with more modern coax. Below the RG-303 from the relay to output RF connector is in place.

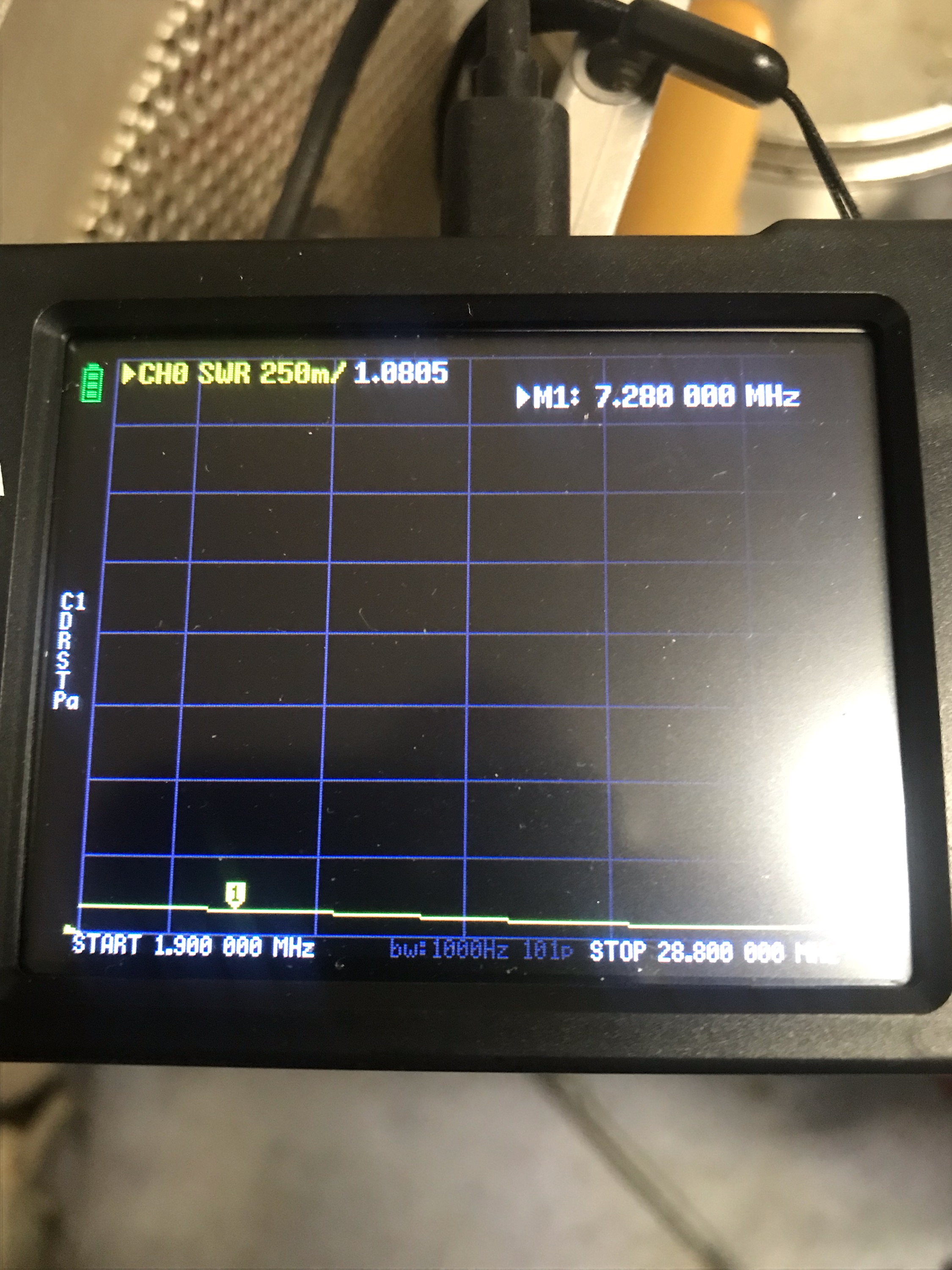

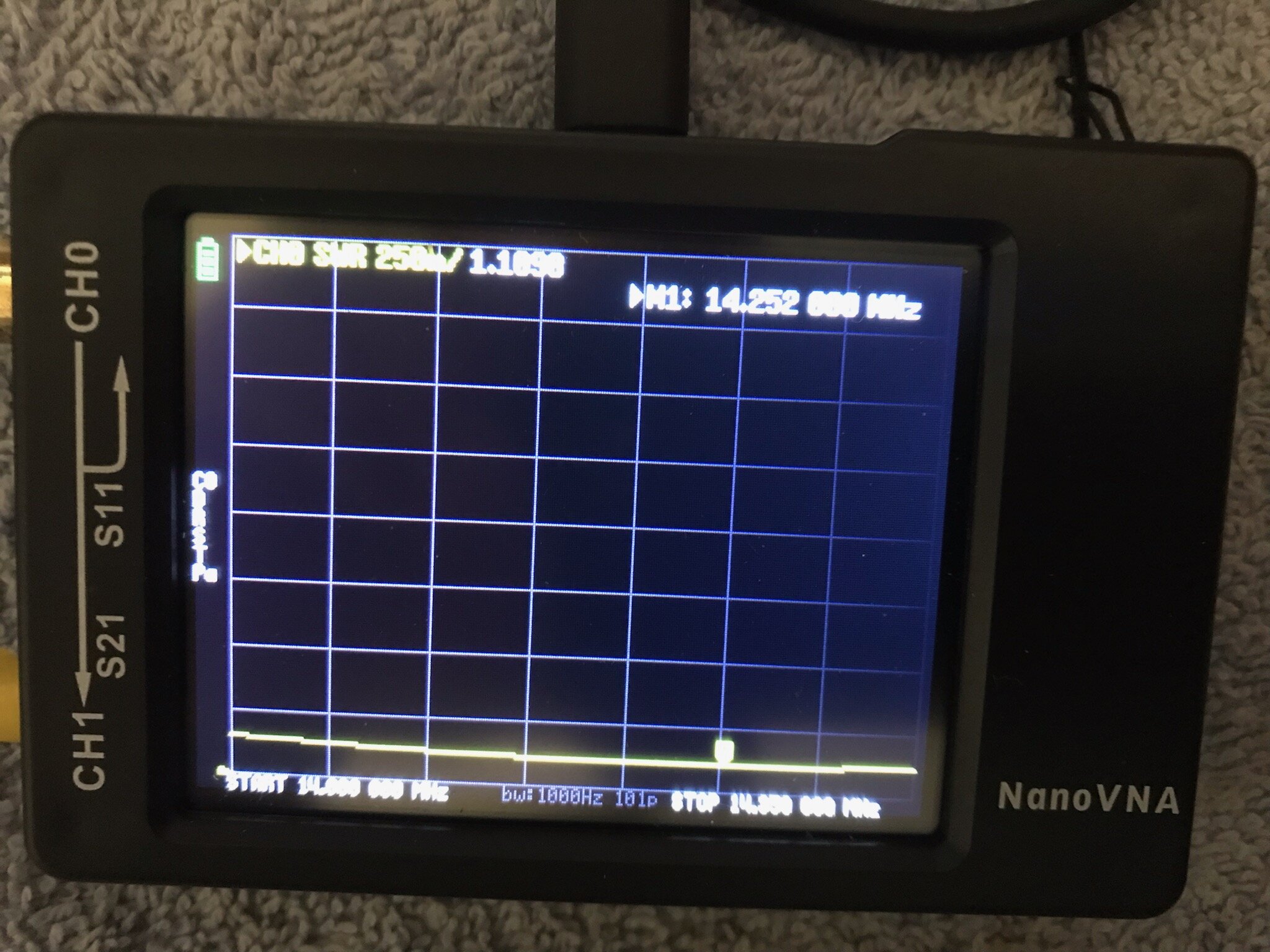

Time to test and "tweak" pass thru SWR. I guess I didn't take a picture of the pass thru SWR measurement before modification but if memory serves it was in the neighborhood of 2:1 on most if not all bands. The VNA was connected to the input S0-239 and a dummy load was connected to the output S0-239. No A/C power, no tubes installed etc. In other words the amplifier was safe to put hands inside. A variable trimmer capacitor was temporarily soldered between relay terminal 9 and chassis ground and the VNA was set up to sweep from the low end of 80 meters to the upper end of 10 meters. when the "sweet spot" was found the trimmer was measured and a 47pF silver mica capacitor was added between relay contact #9 and ground.

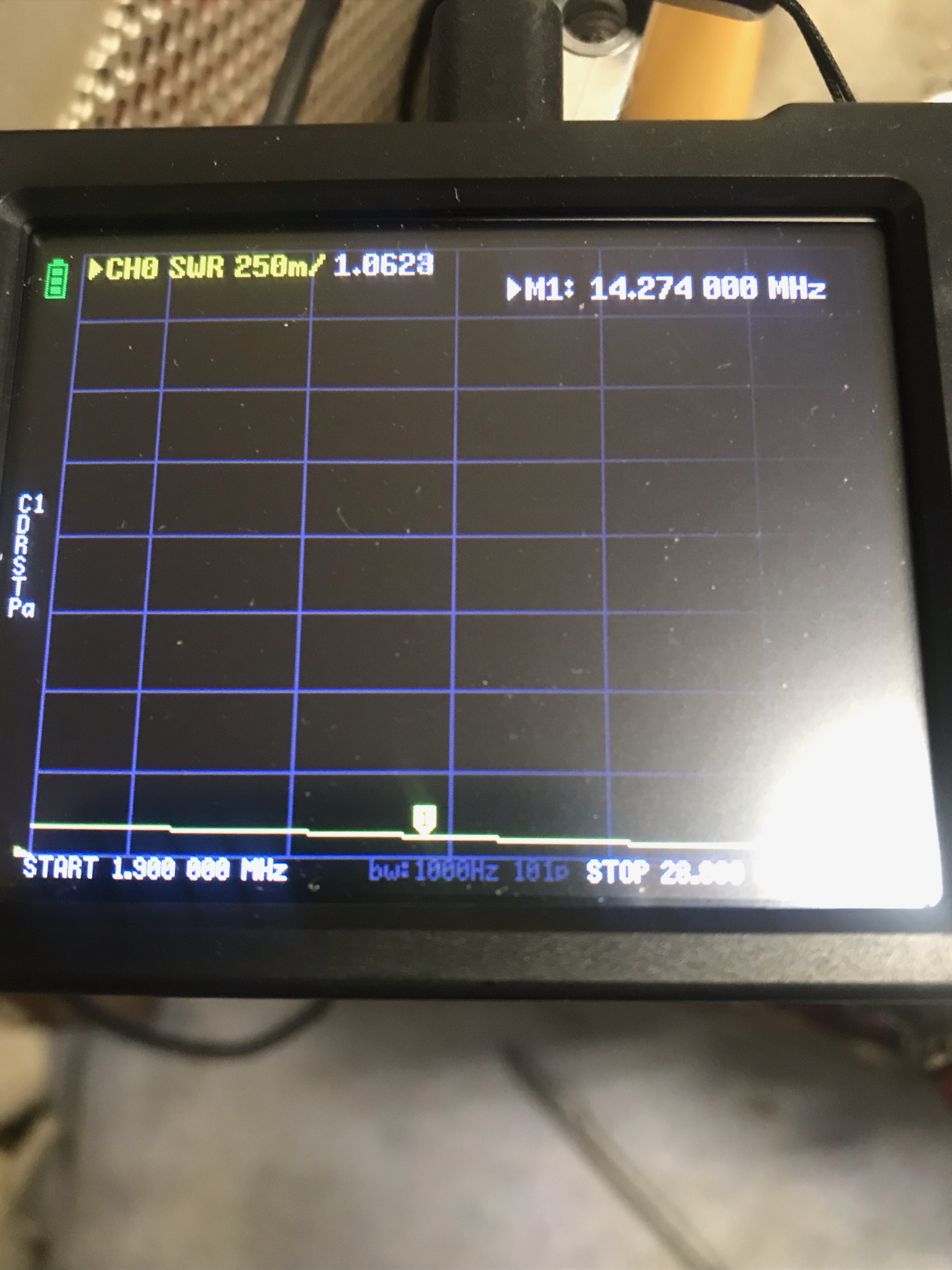

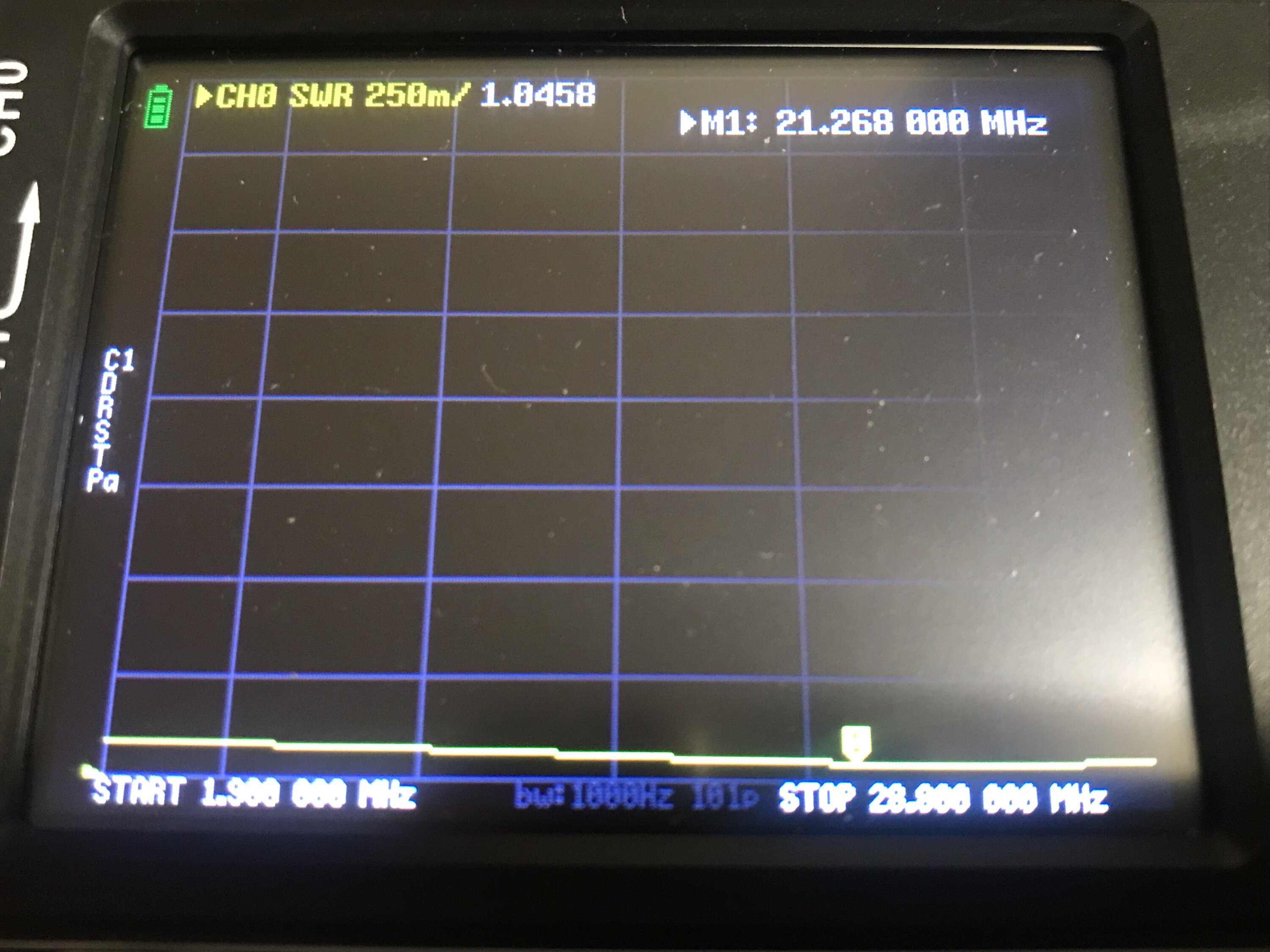

Below are a couple of measurements on various bands. I do have pictures of all band measurements using the VNA but you get the idea. In the end, all bands pass thru SWR were less than 1:1.1. I did remove the single 47pF 500V silver mica capacitor and used 2 paralleled 22pF 500V capacitors.

The ALC circuit of the amplifier was removed. RF drive should be limited but most transceivers will not be capable of overdriving the 3-500Z's.

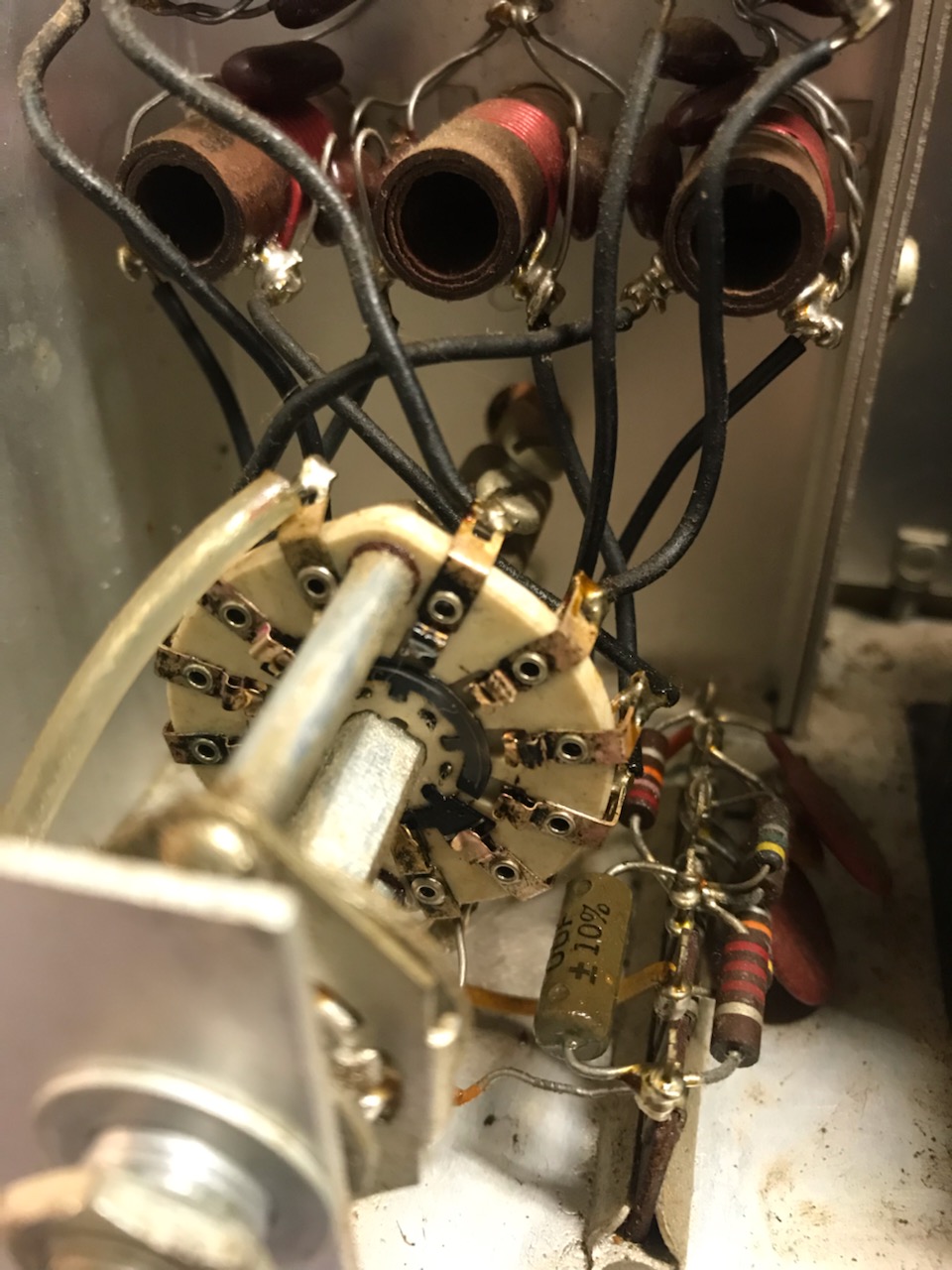

This terminal strip contains the ALC circuit. Removal was easy enough and made it a bit easier to align the input tune circuit.

More on the input tuning next time.

73

David

The internal coax runs were replaced with more modern coax. Below the RG-303 from the relay to output RF connector is in place.

Time to test and "tweak" pass thru SWR. I guess I didn't take a picture of the pass thru SWR measurement before modification but if memory serves it was in the neighborhood of 2:1 on most if not all bands. The VNA was connected to the input S0-239 and a dummy load was connected to the output S0-239. No A/C power, no tubes installed etc. In other words the amplifier was safe to put hands inside. A variable trimmer capacitor was temporarily soldered between relay terminal 9 and chassis ground and the VNA was set up to sweep from the low end of 80 meters to the upper end of 10 meters. when the "sweet spot" was found the trimmer was measured and a 47pF silver mica capacitor was added between relay contact #9 and ground.

Below are a couple of measurements on various bands. I do have pictures of all band measurements using the VNA but you get the idea. In the end, all bands pass thru SWR were less than 1:1.1. I did remove the single 47pF 500V silver mica capacitor and used 2 paralleled 22pF 500V capacitors.

The ALC circuit of the amplifier was removed. RF drive should be limited but most transceivers will not be capable of overdriving the 3-500Z's.

This terminal strip contains the ALC circuit. Removal was easy enough and made it a bit easier to align the input tune circuit.

More on the input tuning next time.

73

David

align the input tune circuit.

A gen-yoo-wine unvarnished PITA, that. Hope it goes smoothly.

If you have a HV breakdown tester, taking the red wires from the HV transformer loose, and checking for leakage current from the red wire to ground will reveal a transformer getting ready to arc over. Not fun when that happens.

Or cheap. Seen it too many times.

At least the two cathode pins on the tube sockets are the same color as the other three. If those two spring contacts are darkened at all it's a bad sign.

73

If you have a HV breakdown tester,

Yep, having a FLUKE solid state Meg'r has been a blessing!

One of the fine tools had available as 40-year Journeyman Electrician.

Same with fluke O-scope and couple different AC/DC DVOM clamp meters!

Continuing on with the Tuned Input tuning.......

Thankfully this amplifier is 50+ years old. There has been much written and documented to help me along the way with this amp. I could not have done it if not for all of those before me.

Keeping in mind when this amplifier was developed most if not all transceivers were tube final radios and input matching was not near as critical as todays transistor final radios.

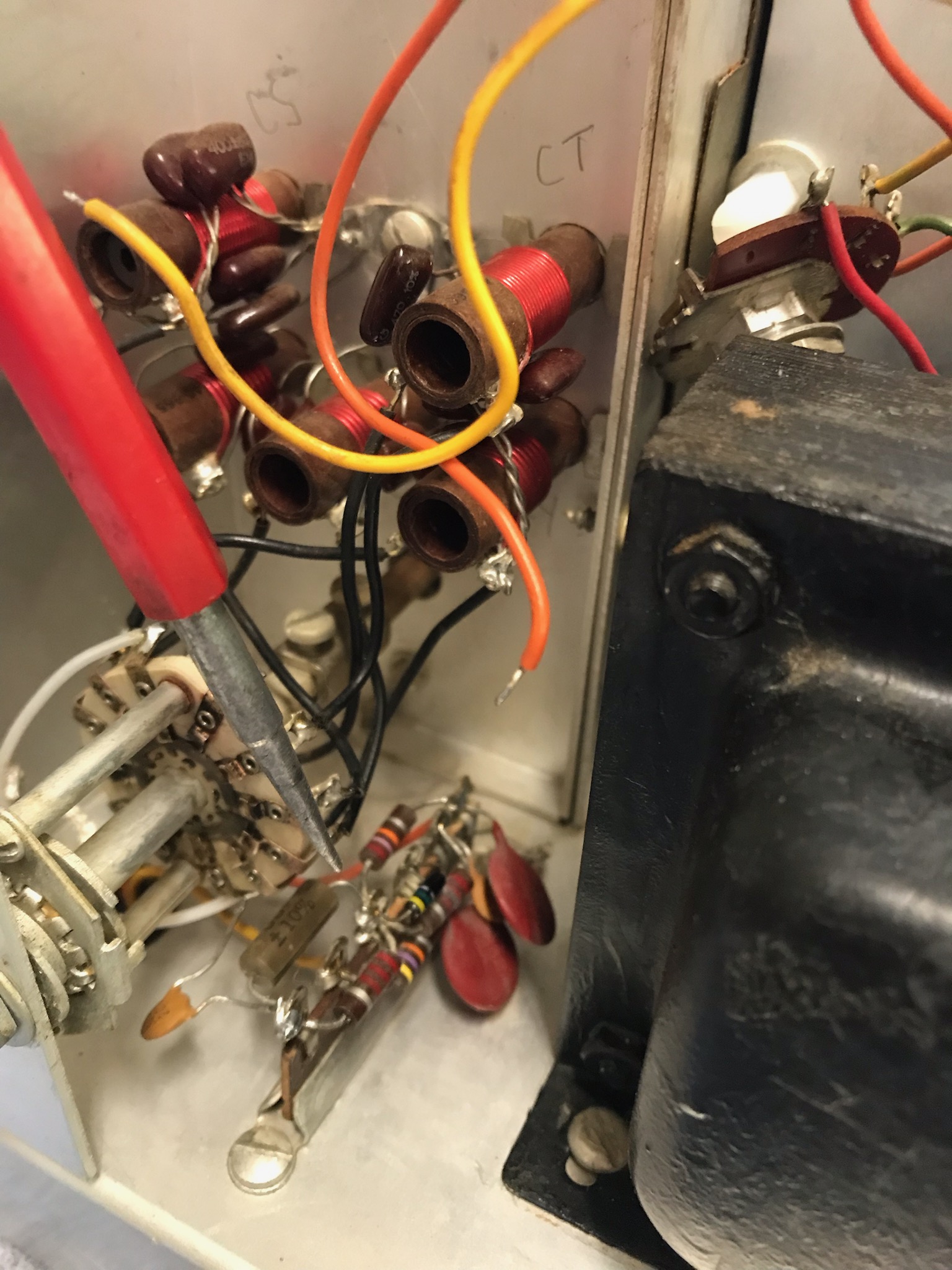

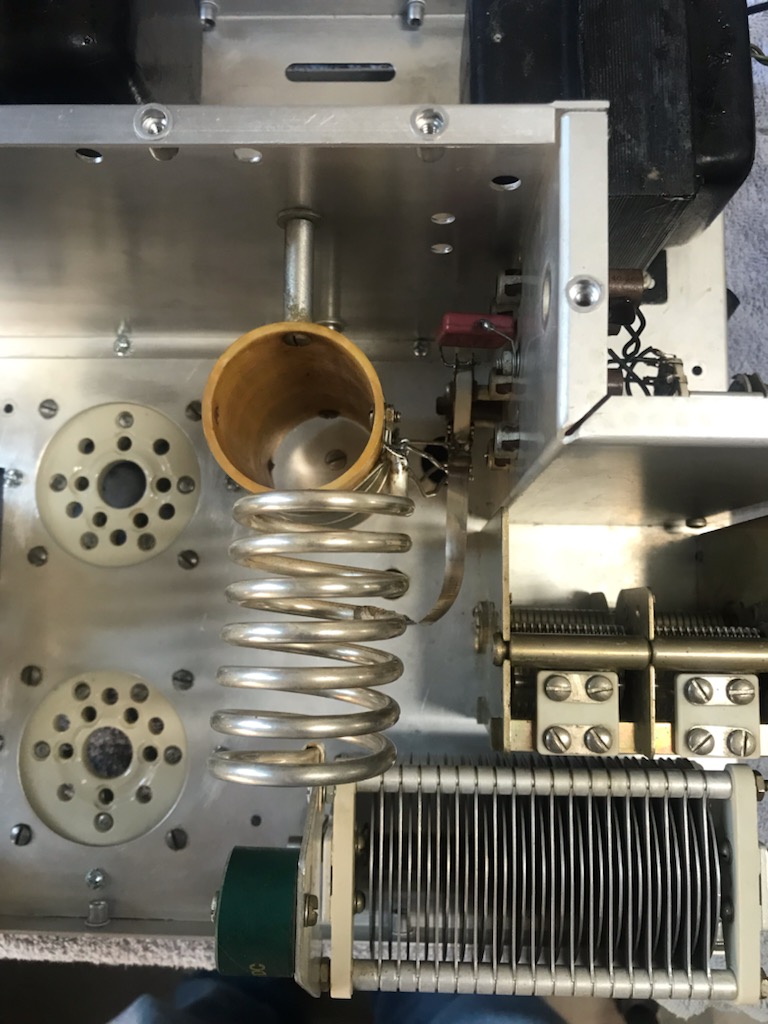

This is the area of interest for this portion of the project. This picture only shows 3 of the 5 input circuits but the modification is very similar for each band.

The goal is to increase the "Q" of each circuit. Too much "Q" and the bandwidth will be too small - SWR will be very flat on very narrow portion of the band.. Too little "Q" and the tuning match will be too wide and no amount of turning the inductor slug will bring the input SWR into an acceptable range.

Rich Measure's states this better than I can.

(Below copied from AG6K)

Increasing both capacitances will lower the operating frequency of the tuned-input, so L must be decreased to bring the frequency back up to where it started. This can be accomplished by removing turns of wire from L, and by adjusting the inductor's tuning slug.

It is important to keep in mind that the matching ratio of a tuned input circuit can not be changed by adjusting the slug-tuned inductor alone. In order to arrive at the optimum SWR, Two components must be adjusted in order to change the matching ratio of a tuned input circuit.

The inductor for each band was removed one at a time and in most cases turns were removed from the coil and the input and output capacitors were (in most cases) increased in value.

The assembly was installed and the circuit was tested using the VNA at the input connector and a dummy load at the output connector. Resistors were temporarily installed from the cathodes of the tube sockets to the grid pins of the socket to simulate the loaded resistance of the tube. The appropriate band was selected and swept for the frequency involved. The tuning slug was adjusted for the best match as reflected on the VNA. This was all done without powering up the amplifier but will need slight adjustment under full power when all other work is done.

Below is the input section after the 80M, 20M and 15M coils and capacitors were modified. 40M on the top right and 10M on the bottom right.

Now for a few "results" pictures.

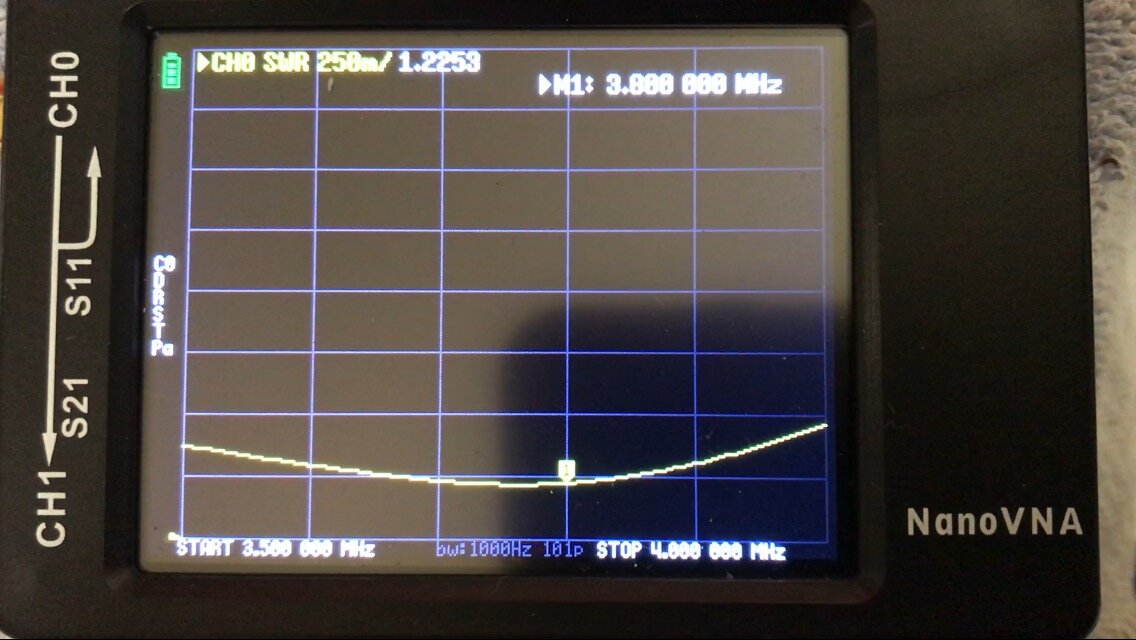

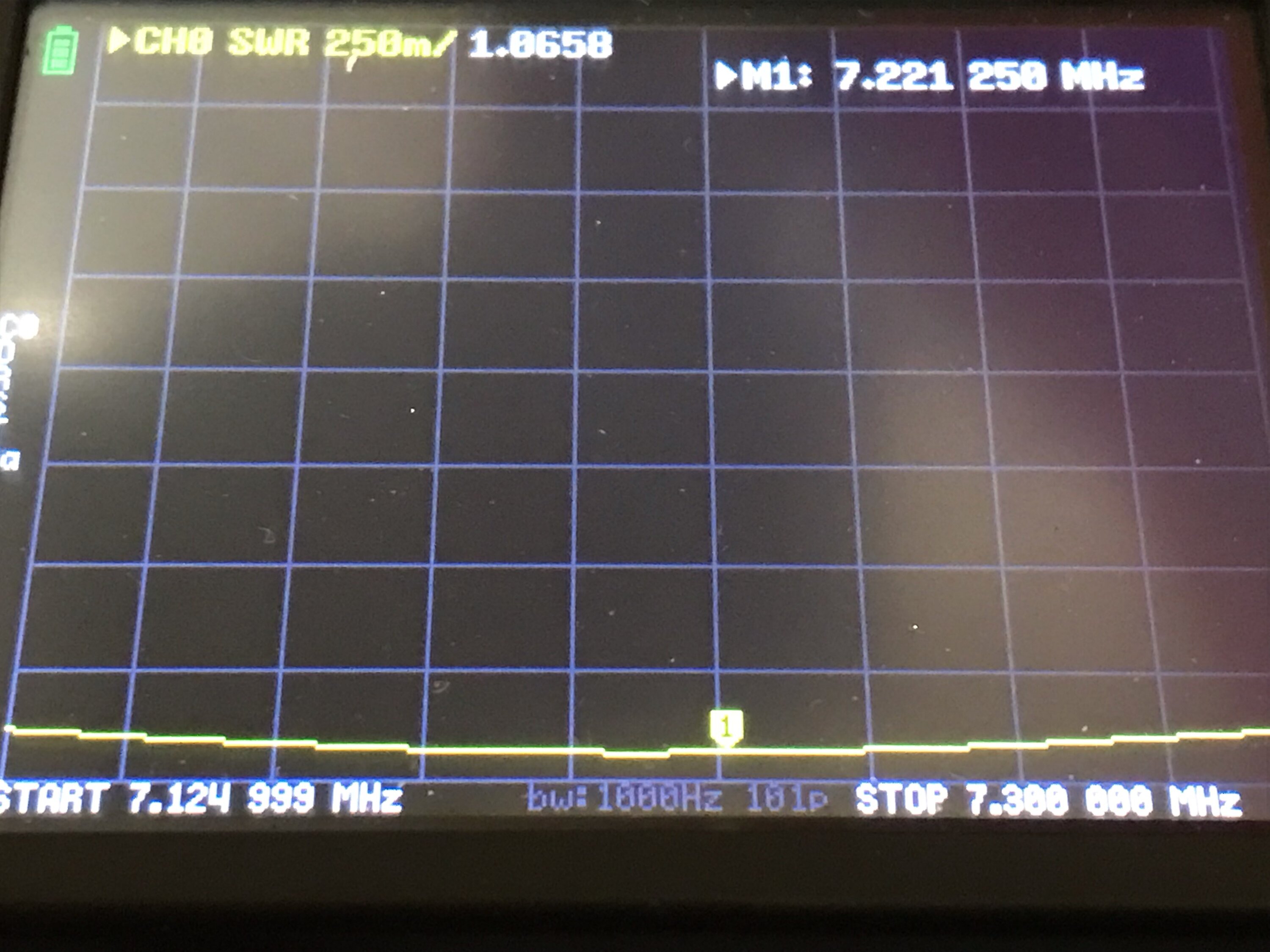

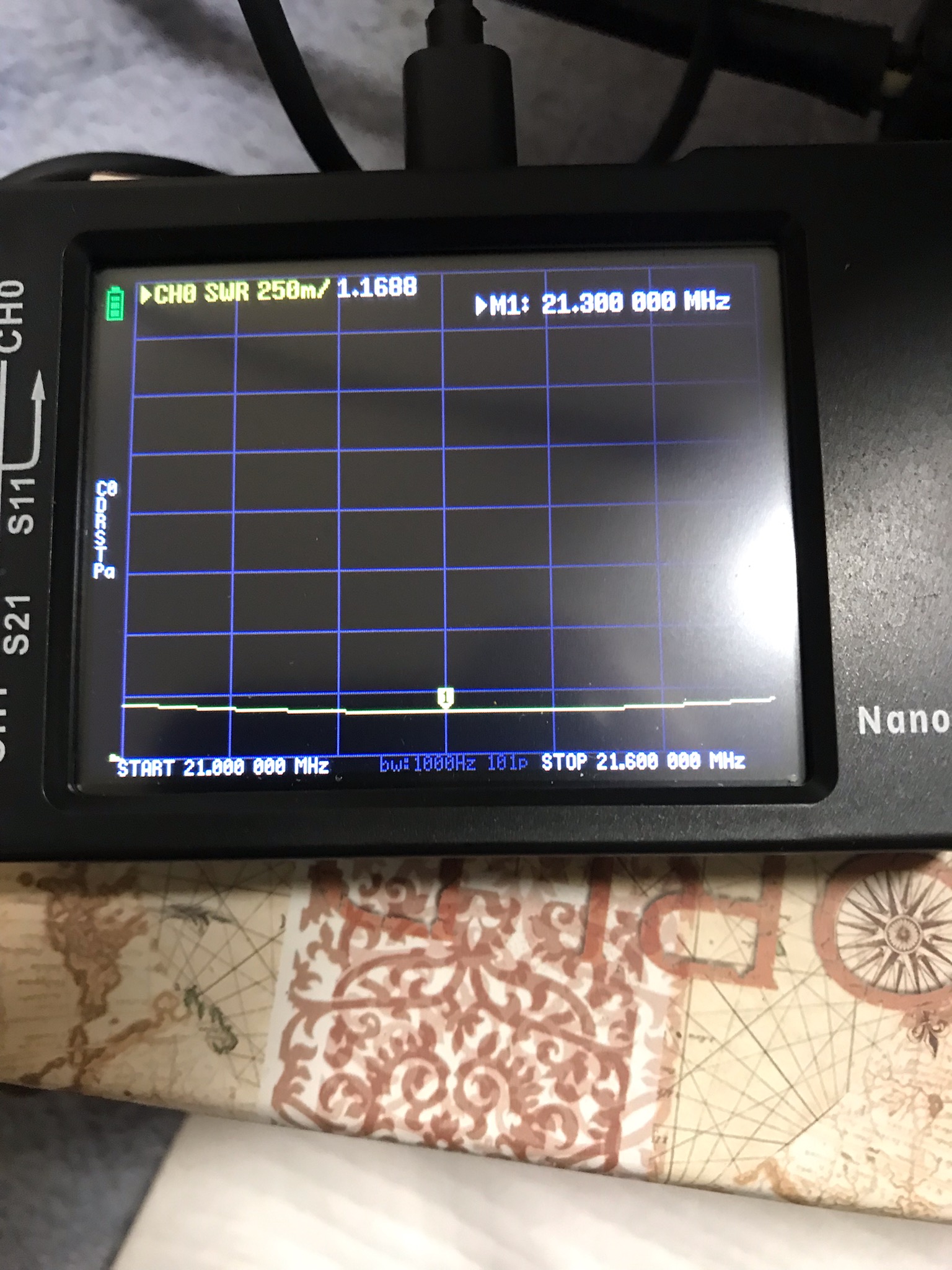

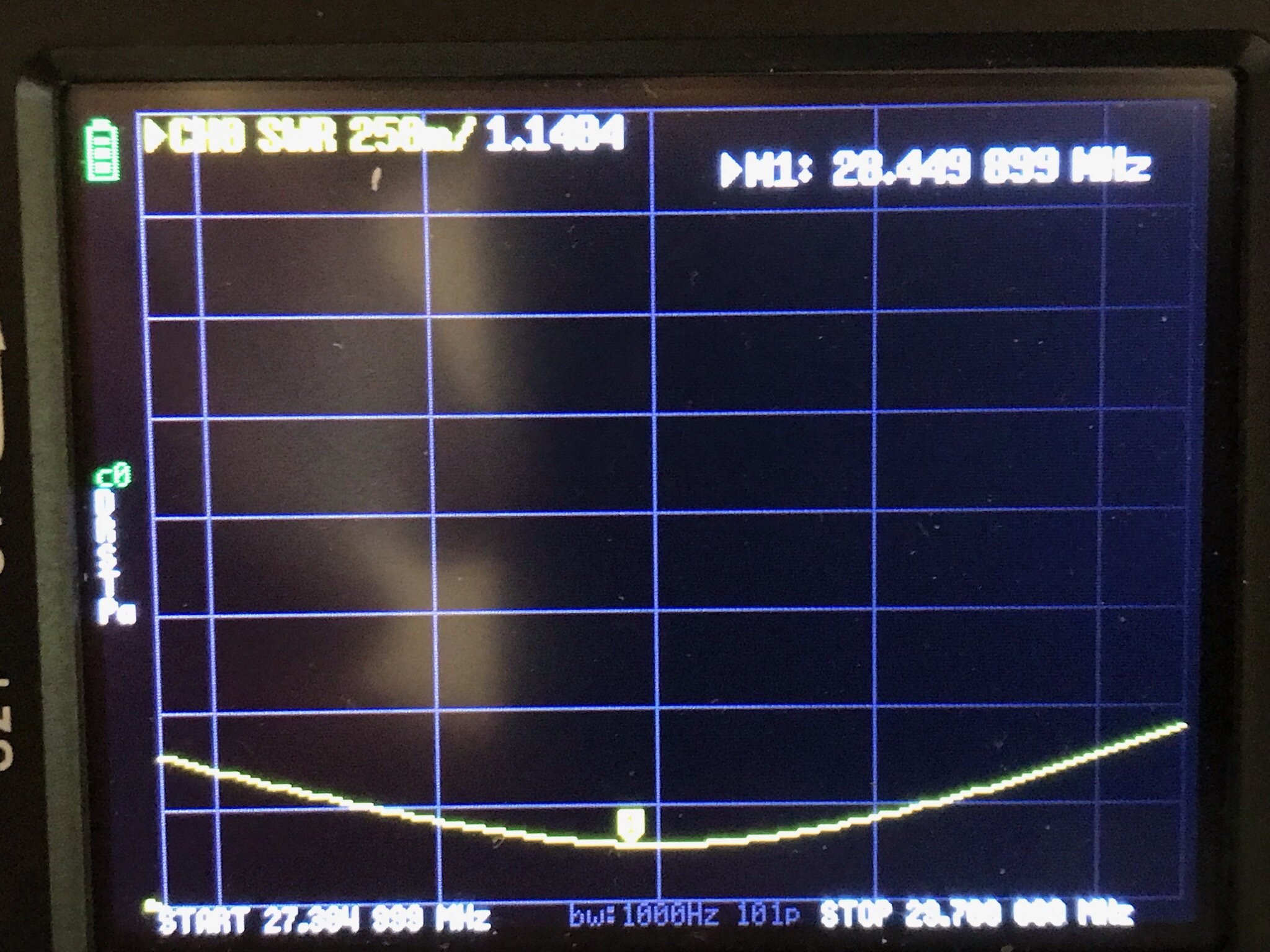

In all cases, each vertical graduation on the VNA is .2 SWR.

i.e. The first horizontal line from the bottom of the scale represents 1.2:1. The second horizontal line is 1.4:1, the third is 1.6:1 etc

80 meter result

40 Meter result

20 Meter result

15 Meter result

10 Meter result

I agree with @nomadradio. A PITA!!

On to the next episode.

73

David

Thankfully this amplifier is 50+ years old. There has been much written and documented to help me along the way with this amp. I could not have done it if not for all of those before me.

Keeping in mind when this amplifier was developed most if not all transceivers were tube final radios and input matching was not near as critical as todays transistor final radios.

This is the area of interest for this portion of the project. This picture only shows 3 of the 5 input circuits but the modification is very similar for each band.

The goal is to increase the "Q" of each circuit. Too much "Q" and the bandwidth will be too small - SWR will be very flat on very narrow portion of the band.. Too little "Q" and the tuning match will be too wide and no amount of turning the inductor slug will bring the input SWR into an acceptable range.

Rich Measure's states this better than I can.

(Below copied from AG6K)

Increasing both capacitances will lower the operating frequency of the tuned-input, so L must be decreased to bring the frequency back up to where it started. This can be accomplished by removing turns of wire from L, and by adjusting the inductor's tuning slug.

It is important to keep in mind that the matching ratio of a tuned input circuit can not be changed by adjusting the slug-tuned inductor alone. In order to arrive at the optimum SWR, Two components must be adjusted in order to change the matching ratio of a tuned input circuit.

The inductor for each band was removed one at a time and in most cases turns were removed from the coil and the input and output capacitors were (in most cases) increased in value.

The assembly was installed and the circuit was tested using the VNA at the input connector and a dummy load at the output connector. Resistors were temporarily installed from the cathodes of the tube sockets to the grid pins of the socket to simulate the loaded resistance of the tube. The appropriate band was selected and swept for the frequency involved. The tuning slug was adjusted for the best match as reflected on the VNA. This was all done without powering up the amplifier but will need slight adjustment under full power when all other work is done.

Below is the input section after the 80M, 20M and 15M coils and capacitors were modified. 40M on the top right and 10M on the bottom right.

Now for a few "results" pictures.

In all cases, each vertical graduation on the VNA is .2 SWR.

i.e. The first horizontal line from the bottom of the scale represents 1.2:1. The second horizontal line is 1.4:1, the third is 1.6:1 etc

80 meter result

40 Meter result

20 Meter result

15 Meter result

10 Meter result

I agree with @nomadradio. A PITA!!

On to the next episode.

73

David

Last edited:

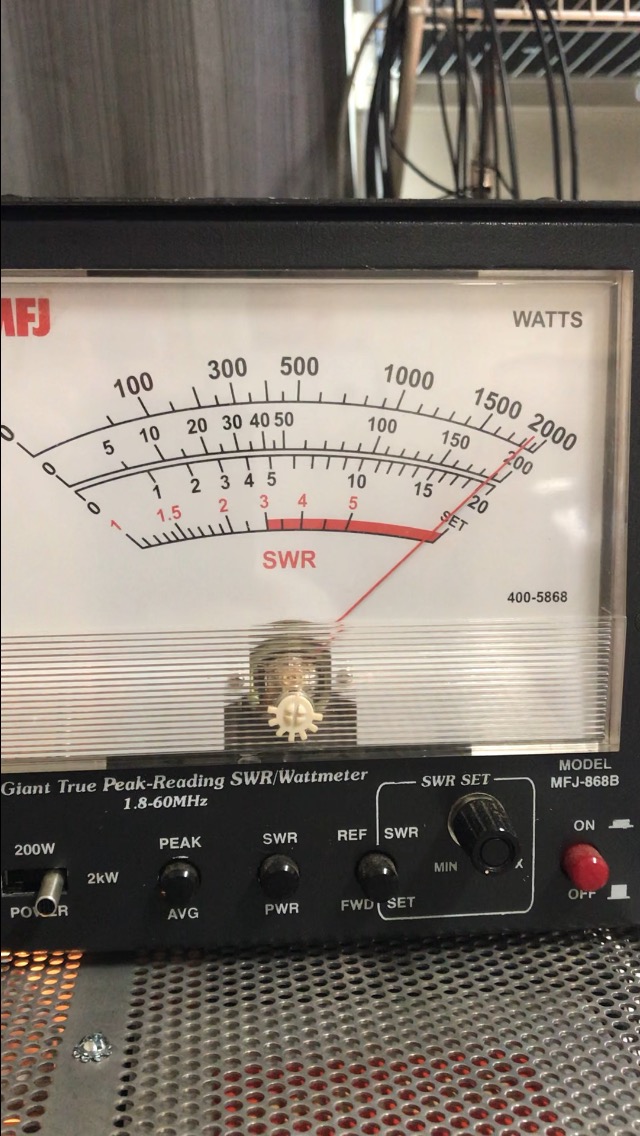

I was able to squeeze in some full power testing today. (This was done today 1/9/22)

The amplifier is still wired for 110Vac input. The testing was done on 80 meters in the amp's SSB power position with the output terminated in a dummy load.

I did not get a picture of my cross needle SWR meter between the Kenwood and the amplifier but it showed no reflected power. I'm thankful for that because I do not relish working on a powered up amplifier.

Results below.

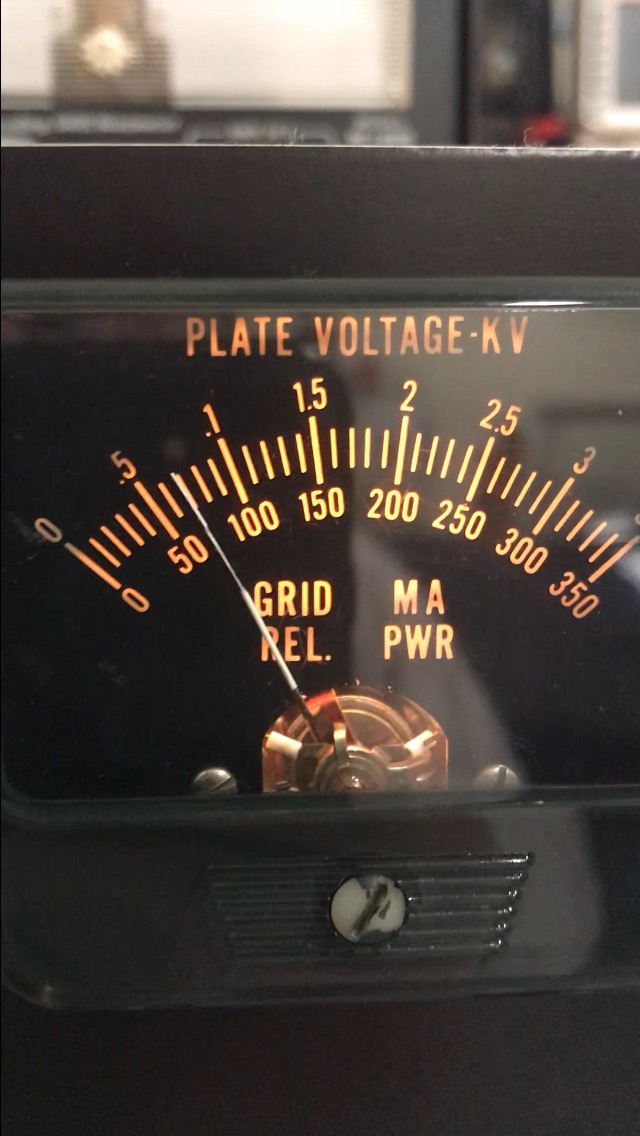

Tested on 3.80010 LSB

100 watts input power to SB-220

Output from SB-220

Grid Ma reading at 1800 watts output

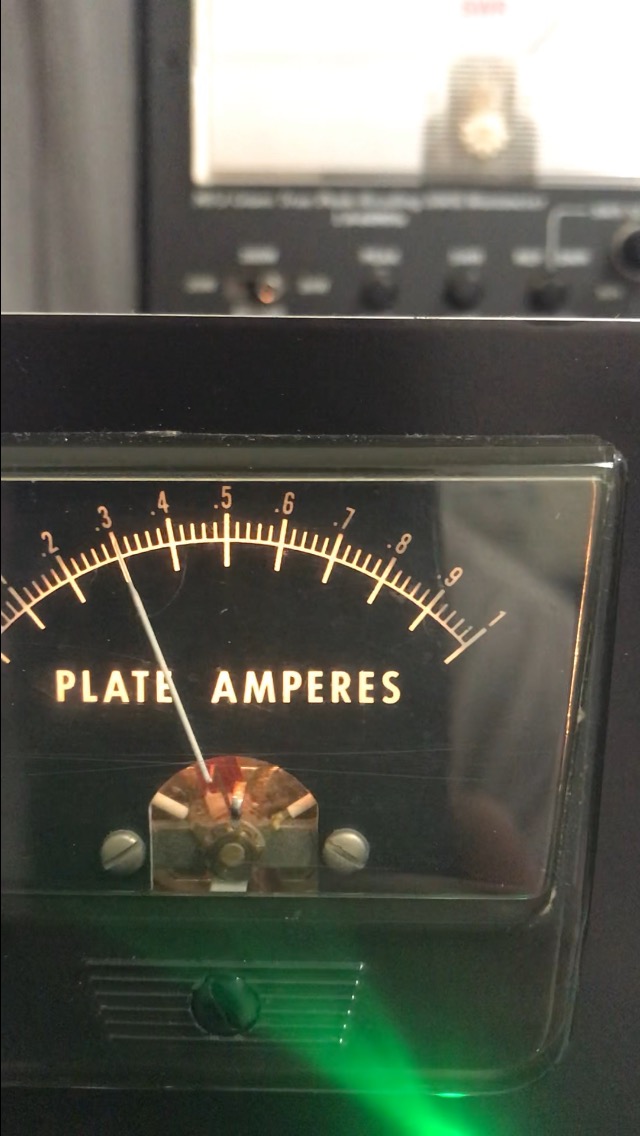

Plate Amp reading at 1800 watts output

There was testing done on 80 meters at 30 watts input CW prior to this full power testing.I am impressed that the tubes appear to be good. As far as I know the amplifier has been in storage for around 20 years.

It looks like this will be a survivor.

73

David

The amplifier is still wired for 110Vac input. The testing was done on 80 meters in the amp's SSB power position with the output terminated in a dummy load.

I did not get a picture of my cross needle SWR meter between the Kenwood and the amplifier but it showed no reflected power. I'm thankful for that because I do not relish working on a powered up amplifier.

Results below.

Tested on 3.80010 LSB

100 watts input power to SB-220

Output from SB-220

Grid Ma reading at 1800 watts output

Plate Amp reading at 1800 watts output

There was testing done on 80 meters at 30 watts input CW prior to this full power testing.I am impressed that the tubes appear to be good. As far as I know the amplifier has been in storage for around 20 years.

It looks like this will be a survivor.

73

David

Last edited:

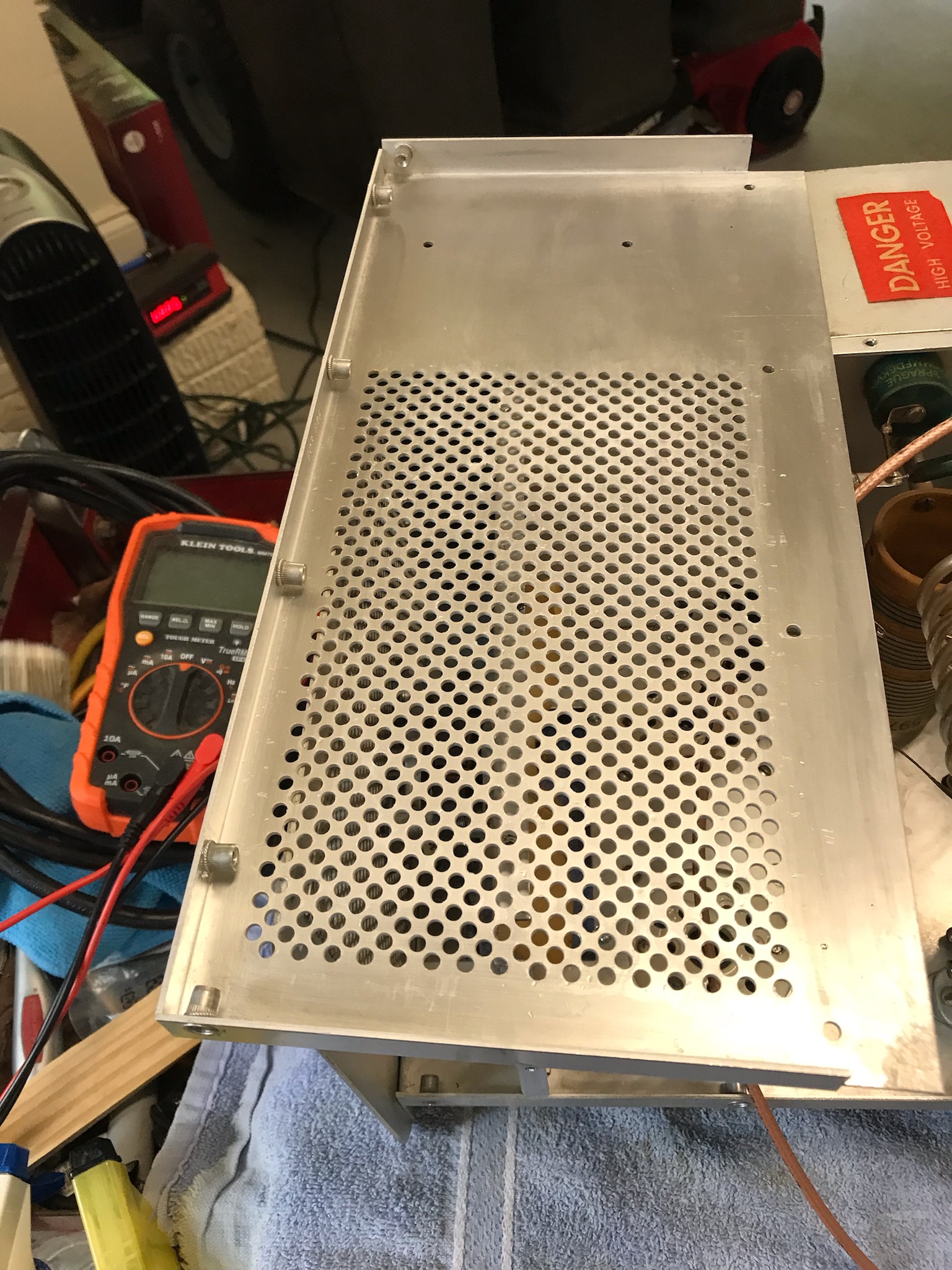

Just a few more picture for informational purposes.

6/32 Rivnuts installed to eliminate sheet metal screws About 50 of them throughout.

6/32 Rivnuts installed to eliminate sheet metal screws About 50 of them throughout.

And a few more for those interested.

Nylon 6/32 screws under filter bank to support the Harbach Soft Start module. Nylon stand off's were used under the chassis to hold the circuit board. One of the reasons the filter bank was installed at least 3 times (maybe 7 or 8!)

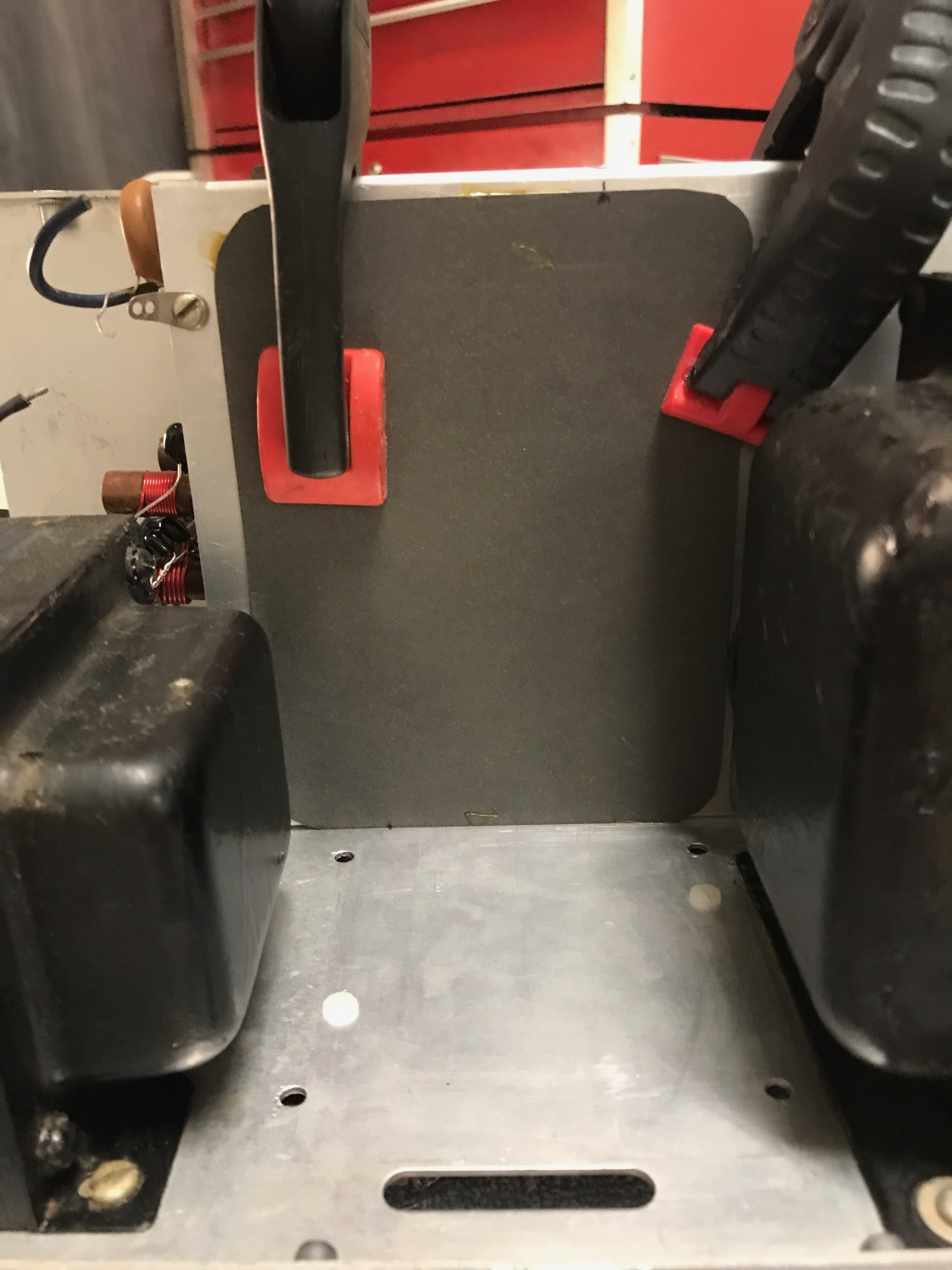

New "Fish Paper" (insulator) being glued to the chassis after all fasteners behind it were secure.

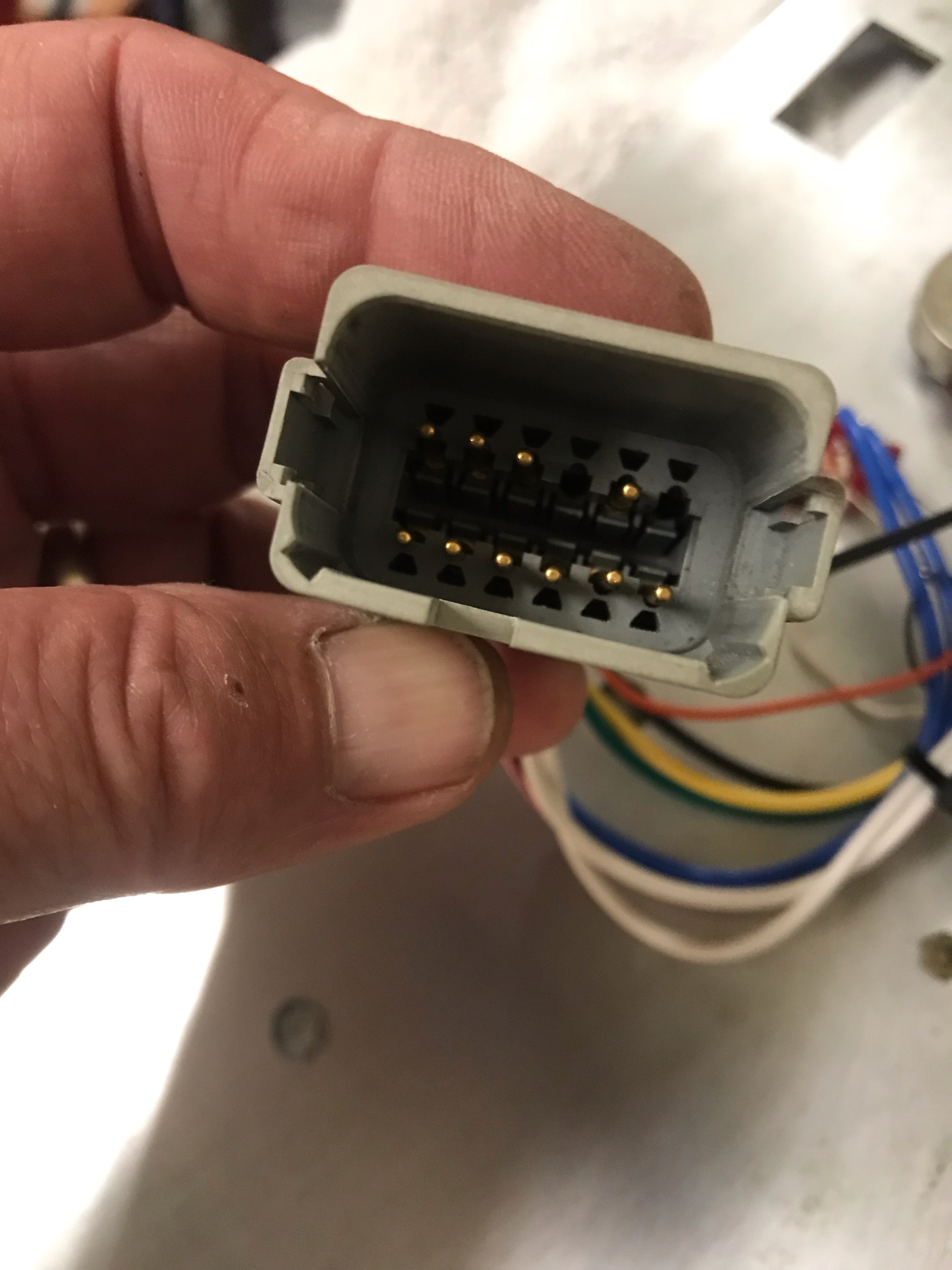

Connector added to all front panel wiring to facilitate front panel removal for service, adjustment etc without a soldering iron.

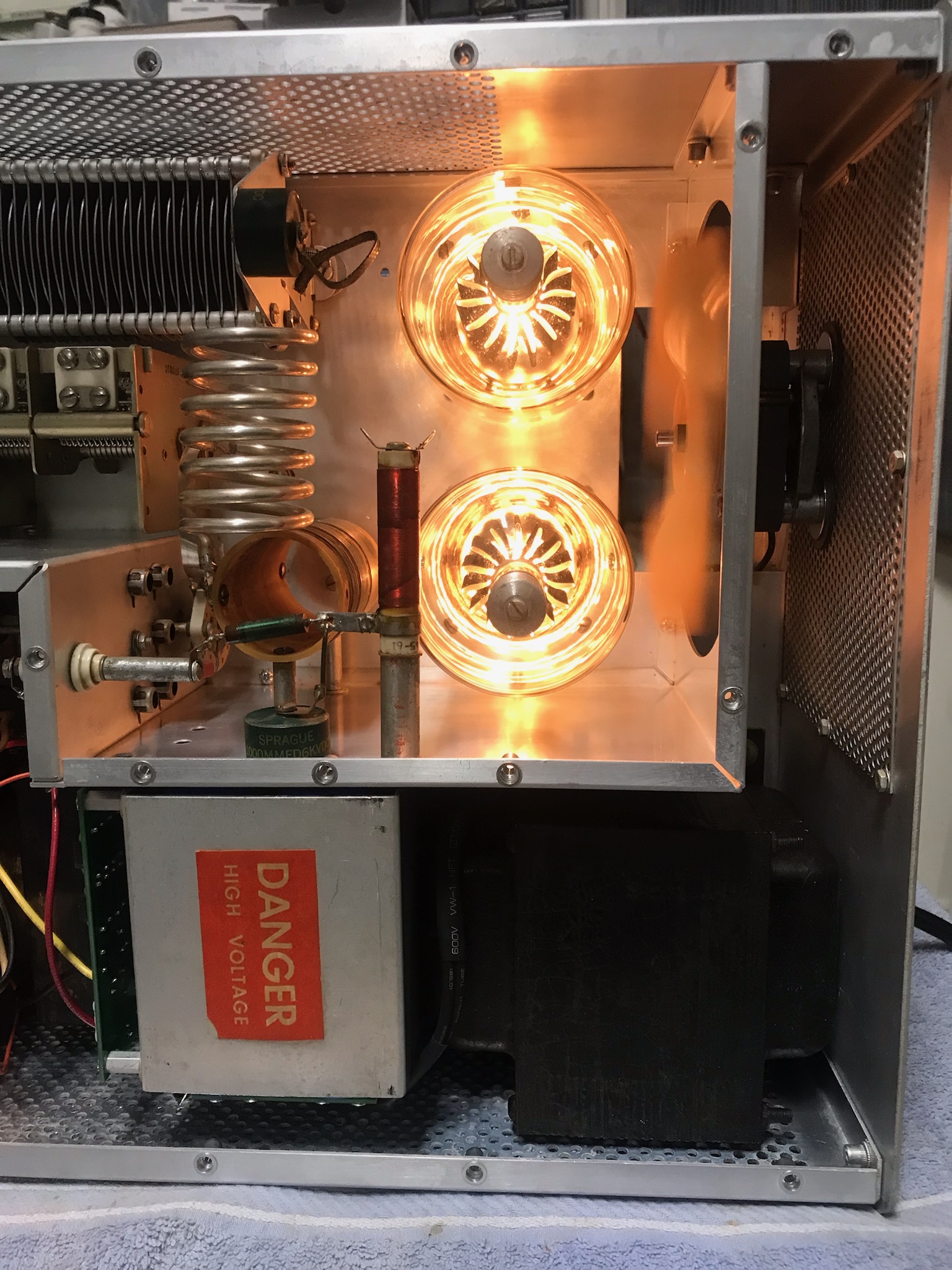

This is what I called the "Beauty Shot". Full filament voltage to the 50 year old tubes.

New Parasitic Suppressors installed

Air conditioner coil cleaner was used on all the aluminum panels to bring them back to their original glory. Got to work fast with a scotch brite pad while wet or the panels get a white stain on them from the acid.

73

David

Nylon 6/32 screws under filter bank to support the Harbach Soft Start module. Nylon stand off's were used under the chassis to hold the circuit board. One of the reasons the filter bank was installed at least 3 times (maybe 7 or 8!)

New "Fish Paper" (insulator) being glued to the chassis after all fasteners behind it were secure.

Connector added to all front panel wiring to facilitate front panel removal for service, adjustment etc without a soldering iron.

This is what I called the "Beauty Shot". Full filament voltage to the 50 year old tubes.

New Parasitic Suppressors installed

Air conditioner coil cleaner was used on all the aluminum panels to bring them back to their original glory. Got to work fast with a scotch brite pad while wet or the panels get a white stain on them from the acid.

73

David

Now THAT'S the way to do it! Rock on!

And before bed, be sure to include the HV transformer in your prayers. It has already outlived a lot of its age bracket.

73

And before bed, be sure to include the HV transformer in your prayers. It has already outlived a lot of its age bracket.

73

It looks like this is a finished project.

The last installment (yesterday) included changing the input to 220Vac, installing the Harbach Soft Start and applying Heathkit Service Bulletin SB-220-27-(Copied from a Word Document and pasted below). I was told that this amplifier had already suffered one low voltage transformer failure in its past. The drawing/schematic was not included in this bulletin that I found but it wasn't hard to figure out.

April 26, 1985

SB-220 Bulletin No:

2 KW Linear Amplifier SB-220-27

T2 Overheats And Fails When Operating On 220 Volt Line

When the linear amplifier is wired for 220 volt AC line operation, and

the contacts on SW2 [PN 61-45] or a high voltage transformer winding

opens, excessive current will flow through the primary of low voltage

transformer T2 [PN 54-238],

causing it to fail. To prevent this failure, the black-green lead and

the black-yellow lead of T2 are lifted and connected together with a wire

nut.

To do this, refer to the drawing at the right and remove the black-green

lead at lug 3 of terminal strip AE [the lead from T2 at grommet AK] and

the black-yellow lead at lug 2 of SW2. Connect these wires together with

a wire nut [PN 432-199].

Make this wiring change on units you receive for service which are wired

for 220 volt AC operation. Let the customer know that this wiring change

has been made. If he wants to operate on 120 volts AC, he'll have to

reconnect these wires as shown in the assembly manual.

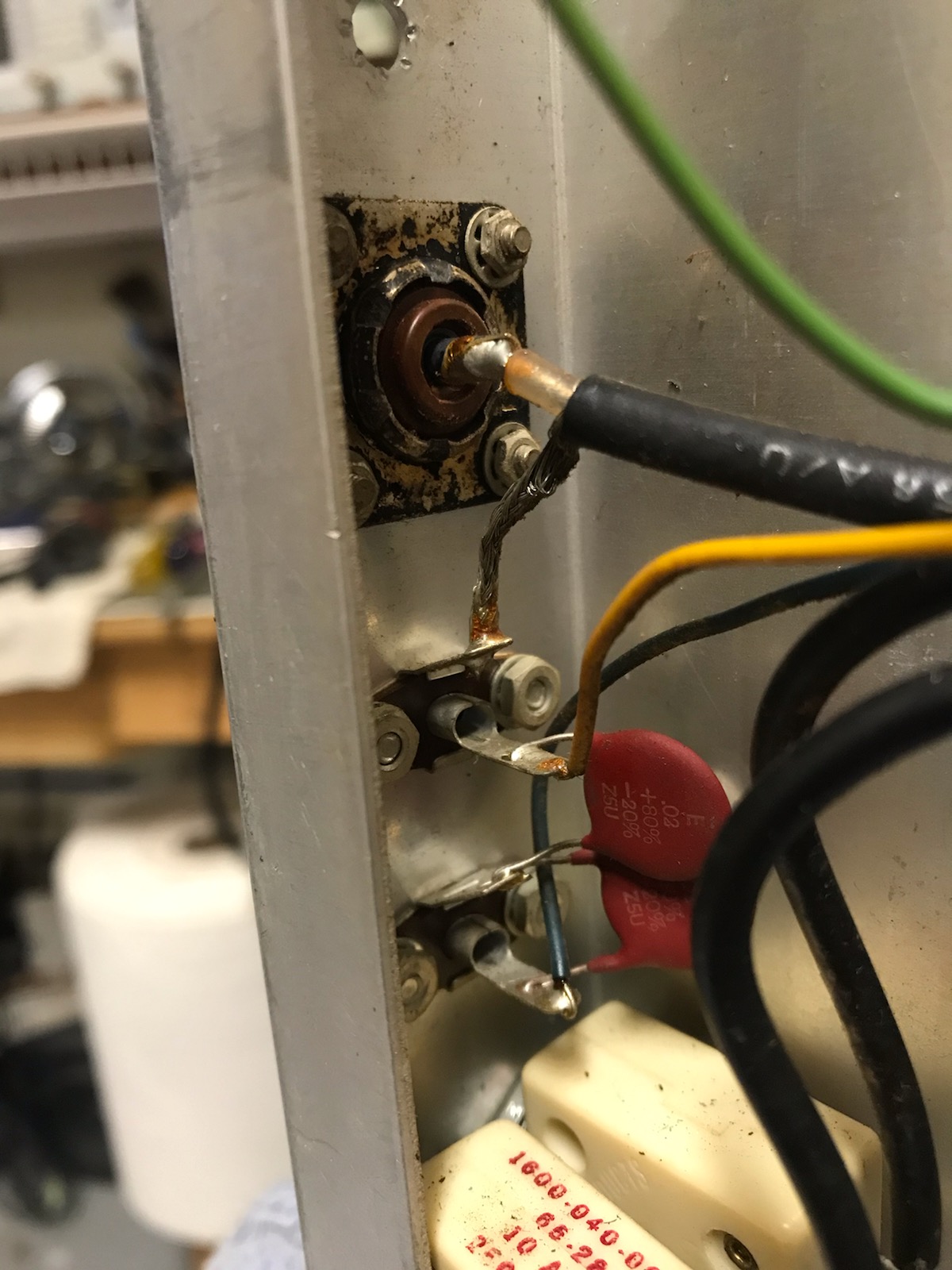

I did not use a wire nut as suggested in the bulletin above but soldered the ends of the 120V primary leads together and covered with 2 layers of heat shrink.

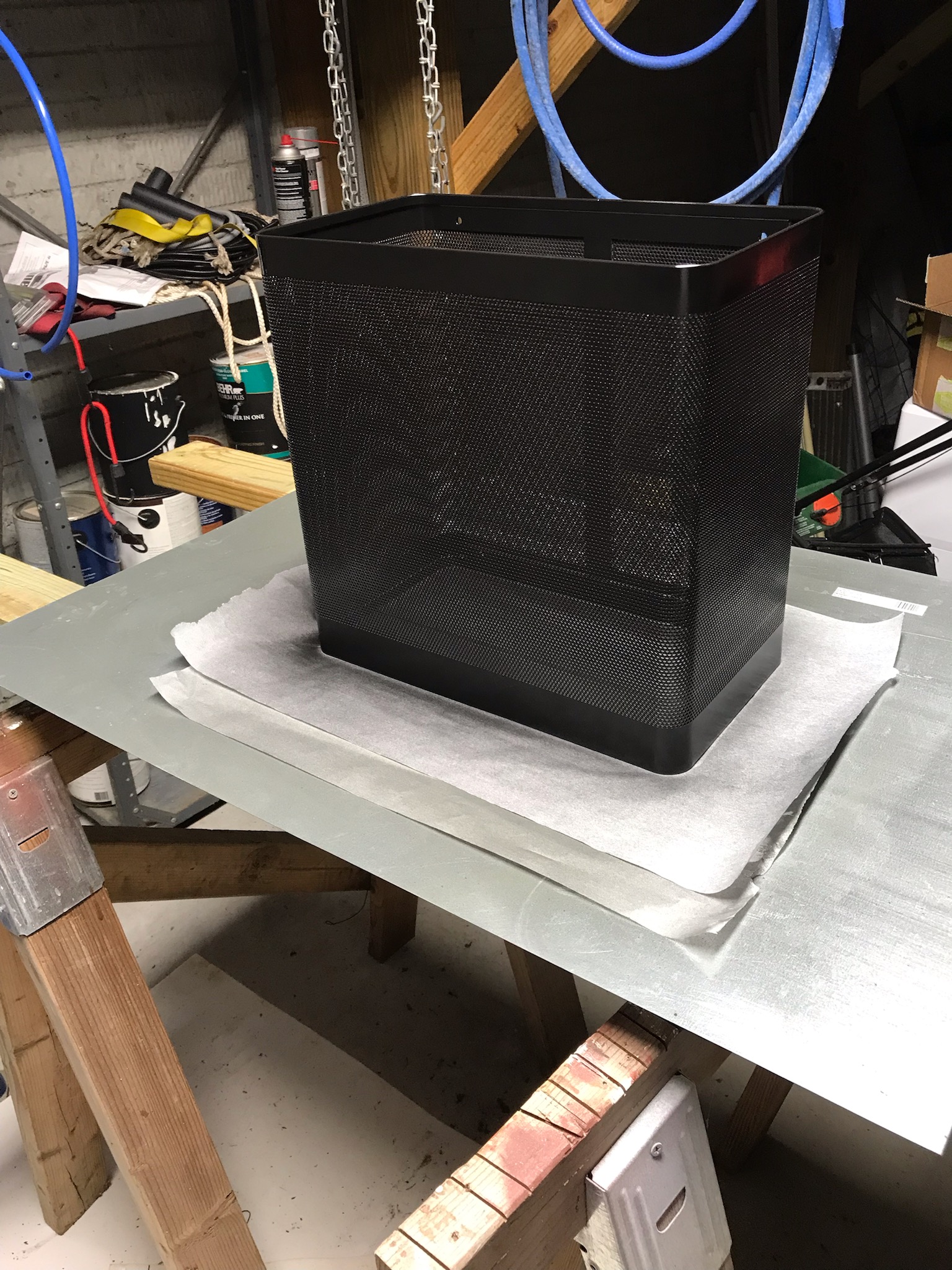

A couple of pictures below with the outer case on the amplifier.

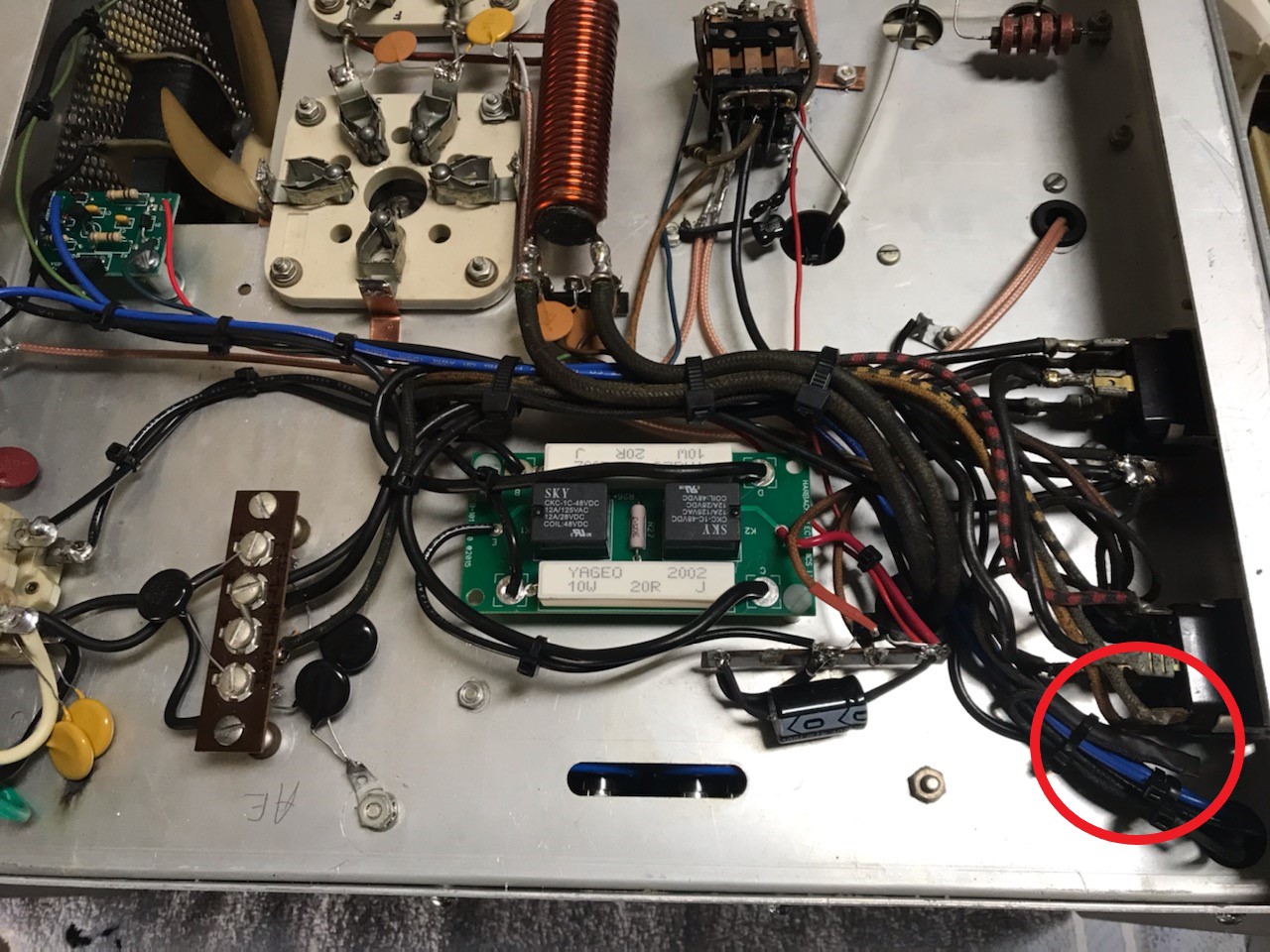

Red circled area is the two filament 120V primary wires connected together per the Heatkit Bulletin.

I like the way this project turned out but am sure this look is not for everybody.

I should build myself one!

73

David

The last installment (yesterday) included changing the input to 220Vac, installing the Harbach Soft Start and applying Heathkit Service Bulletin SB-220-27-(Copied from a Word Document and pasted below). I was told that this amplifier had already suffered one low voltage transformer failure in its past. The drawing/schematic was not included in this bulletin that I found but it wasn't hard to figure out.

April 26, 1985

SB-220 Bulletin No:

2 KW Linear Amplifier SB-220-27

T2 Overheats And Fails When Operating On 220 Volt Line

When the linear amplifier is wired for 220 volt AC line operation, and

the contacts on SW2 [PN 61-45] or a high voltage transformer winding

opens, excessive current will flow through the primary of low voltage

transformer T2 [PN 54-238],

causing it to fail. To prevent this failure, the black-green lead and

the black-yellow lead of T2 are lifted and connected together with a wire

nut.

To do this, refer to the drawing at the right and remove the black-green

lead at lug 3 of terminal strip AE [the lead from T2 at grommet AK] and

the black-yellow lead at lug 2 of SW2. Connect these wires together with

a wire nut [PN 432-199].

Make this wiring change on units you receive for service which are wired

for 220 volt AC operation. Let the customer know that this wiring change

has been made. If he wants to operate on 120 volts AC, he'll have to

reconnect these wires as shown in the assembly manual.

I did not use a wire nut as suggested in the bulletin above but soldered the ends of the 120V primary leads together and covered with 2 layers of heat shrink.

A couple of pictures below with the outer case on the amplifier.

Red circled area is the two filament 120V primary wires connected together per the Heatkit Bulletin.

I like the way this project turned out but am sure this look is not for everybody.

I should build myself one!

73

David

Last edited:

David: Nice stuff Dude!

I did the same color scheme to my last SB-220 when I converted it to 6 meters

The band switch location now houses the "Tunable Input Circuit". I removed that junk "relative output/swr circuit" plugged that switch hole, now just have Grid/HV/Plate amp functions for meters.

Anyway, nice work, hope the operator takes care of it.

Oh, one last item, my last conversion I added a "Hot Rod" B+ transformer.

The B+(HV) is close to 3350 DC (+/- due to local line voltage) made a nice change, reduces the sag down quite measurably.

(1600 watts key down CW/100 w drive) never run it there!

I like to see about 1100-1200w normal operation.

All the Best

Gary/W9FNB

I did the same color scheme to my last SB-220 when I converted it to 6 meters

The band switch location now houses the "Tunable Input Circuit". I removed that junk "relative output/swr circuit" plugged that switch hole, now just have Grid/HV/Plate amp functions for meters.

Anyway, nice work, hope the operator takes care of it.

Oh, one last item, my last conversion I added a "Hot Rod" B+ transformer.

The B+(HV) is close to 3350 DC (+/- due to local line voltage) made a nice change, reduces the sag down quite measurably.

(1600 watts key down CW/100 w drive) never run it there!

I like to see about 1100-1200w normal operation.

All the Best

Gary/W9FNB

dxChat

- No one is chatting at the moment.