The check is simple, just measure the DC current across Test point LEAD to Test point Plug....

Done in SSB mode, No Audio - into a 50 ohm dummy load.

TX - measure and adjust the Bias Pot for respective DRIVER or FINAL - DVM is set for 200mA scale - in SSB mode either USB or LSB.

Can't find the pot, try one or the other - shown above, if they are not adjusting - STOP and recheck your connections.

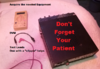

THIS IS WHY YOU PULL BOTH WIRES OFF THEIR STEMS - PREVENTS ERRORS IN ADJUSTING WRONG TP TRIMMER Power doesn't go to the Driver and or Final unless you connect thru the DVM and it should be fused so if you go too far, it will blow it's fuse and protect your investment....

In TX mode, adjust TP trimmer bias to match 50mA - do this for one TP at a time - once completed TURN OFF POWER REMOVE TEST leads reconnect Wire to STEMS and begin to finish up the work...

Verify the Radio does work -

Reapply power,

- - set MODE to AM

- - while on Dummy LOAD

- - key up and verify the S/RF meter shows RF power - if not - verify your work

Once you've set RF power settings by verifying Scale of Meter and Scale on external power meter and you're satisfied they are good, then close up the radio...

But you asked about BIAS DIODES ....

The above check is for this - if the Bias diodes are bad, you won't get any mA reading because the DVM fuse could have blown already - it means you have to locate one of two things...

A short in the Final and or Driver - Blown shorted...or OPEN No power flow or blown DVM fuse.

OR

Bias diodes blown - cannot adjust mA reading to proper mA readings...

To fix the Bias diodes that easy enough - remove the Bias boards - one at a time unsoldered from the main PCB

You can bend the leads of the 1N4148s' to 90 degrees down - at the body - and then unsolder remove the old diode and blob solder the other one in to replace it. Position it carefully but the body can fit in there. If you aren't comfortable with this - apply the diode directly to the back panel using a simple adhesive and rewire it back to the main PCB following proper polarity - see below...

You follow the install with the Diodes UNBANDED end towards the respective Trimmer Pot - the BANDED end goes to Foil Board Ground and you then remount the new diode (either on the bias board or directly) thru to the back panel. On either the board, or as affixed to the rear panel using a simple adhesive to make the body contact the metal of the rear panel for thermal contact.

Ok, also caught you already swapped out those parts from another radio - well while the old ones are out, check them to make sure they are still diodes and only work one way. Keep them and use them back in the 140...

Now as far as the output - did you check for heat?

This also means the SIDE panel by the AM regulator - you may have to recheck the install and make sure you are going directly to the TEST POINTS shown in the above in this post.

Else you may have a failed part in the output network - re-check the work in the Final to output tank and beyond into the output network - it can be a solder "strand" or a blown cap onto a bad antenna connector jumper wire - or the SWR section can have a blown diode making your day...