You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

-

You can now help support WorldwideDX when you shop on Amazon at no additional cost to you! Simply follow this Shop on Amazon link first and a portion of any purchase is sent to WorldwideDX to help with site costs.

Cobra 21 GTL tiny bit forward swing

- Thread starter Puttputtinpup

- Start date

Welcome to the Forum...

Hold on, he has already done several steps that take us to this...

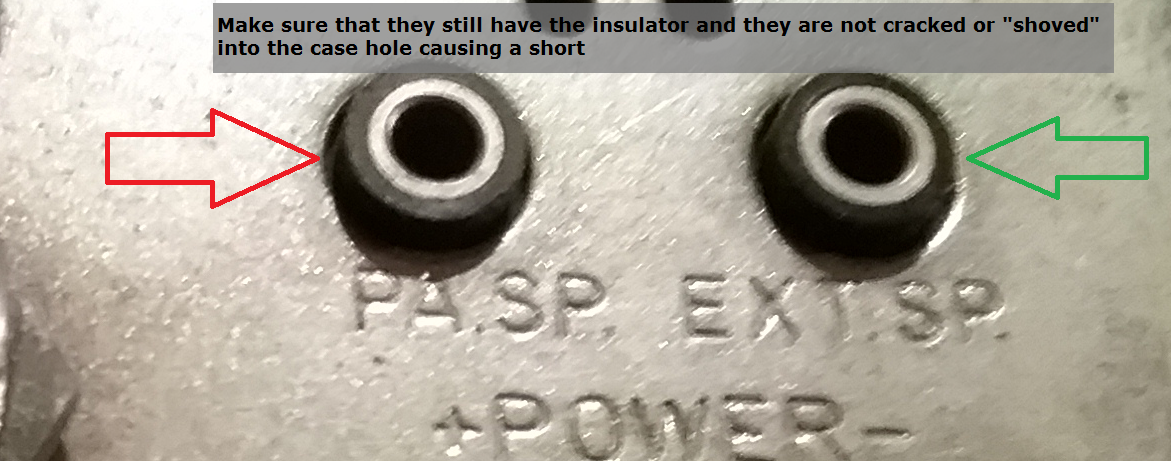

The issue of the no speaker, may be from seized coil onto a shorted or bad wiring harness onto the EXT. SP jack not engaging the tang to allow the internal speaker to recover...So - why no swing or weak - is it shorting to case or something else?

Omg first try your power supply, your doing too much at once,check voltage at final out.

Hold on, he has already done several steps that take us to this...

The issue of the no speaker, may be from seized coil onto a shorted or bad wiring harness onto the EXT. SP jack not engaging the tang to allow the internal speaker to recover...So - why no swing or weak - is it shorting to case or something else?

Last edited:

Yes, thanks - this is your baby, so remember to keep extra "diapers" a.k.a. - Capacitors around for these moments...C104 also looks like it's bad too. It's a 470Uf 10v cap. Can I use a 24v cap here too?

I do have a couple of junk radios that I'll check for comparable caps. If that gets the radio to work, then I'll get some new 24-36v caps and then swap them out.Yes, thanks - this is your baby, so remember to keep extra "diapers" a.k.a. - Capacitors around for these moments...

Thanks a bunch for your help already. Frustrating to a degree I'm sure for seasoned techs to explain things in the simplest of forms to newbies. Yep, I'm learning. Wish I could have taken some electronic courses when I was younger. I enjoy fixing and learning as I do. I appreciate your patience.I'll be staying tuned...

Good luck!

Long night. Headed to bed. Raining here, so I'll be in the basement this afternoon warming up my iron.

That last cap you mentioned the C104 is for smoothing and cleaning up the Power supply to the PLL chip - it's the heart of the radio so you've made really decent progress.

Yes, Electronics is a complex world, but remember - each scenario is different - I may know a radio or two, but each person and their challenges they face are vastly different. Not all radios are the same, neither are their operators.

I'm learning right along with you...

- It's not often do you get a chance to play with something that can provide a lot of learning in return for your effort. You hit the ground running and so far by being careful, you've taken this step and several more onto a radio hobby for enjoyment. If not a training tool for your future.

- I wish you the best of luck, keep going - you're doing fine.

- Slow, little steps makes for more headway than giant leaps that can make you stumble.

Yes, Electronics is a complex world, but remember - each scenario is different - I may know a radio or two, but each person and their challenges they face are vastly different. Not all radios are the same, neither are their operators.

I'm learning right along with you...

I took a look at a couple of my junk radios. Some of those caps looked questionable too, so i ordered an assortment of caps from amazon. Looking at those radios, I may wanna try tackling fixing those too. Later. Plus if I removed any those used caps, the legs would be too short to feed into the board.Either way it's ok, but for safety margin? Use the higher voltage ones...

I'll post any progress after I get my caps and a chance to work on the 21

Handy Andy, I would have posted sooner but the forum's security certificate had expired and I wanted to be sure they fixed it before logging back on.

The little 21 GTL seems to be alive & well again it seems after changing 3 caps. I'll dead key 5watts and swing to 18- 20 most of the time depending on which mic I use.

I bought an assortment of caps from amazon. The 1000ohm was so much smaller in size compared to the original. Actually, they all were smaller in size. Next I might tinker with an echo board & talkback. I wondered how i would identify the correct capacitor solders to remove. I ended up using a set of dividers to measure the center line of the cap then flip the radio over and found the solders.

The meter needle is stuck, but I've fixed those before. The 16ohm internal speaker was bad too, so replaced it with the only one that size I could find but it's an 8ohm. Ext spkr jack works as it should.

The little 21 GTL seems to be alive & well again it seems after changing 3 caps. I'll dead key 5watts and swing to 18- 20 most of the time depending on which mic I use.

I bought an assortment of caps from amazon. The 1000ohm was so much smaller in size compared to the original. Actually, they all were smaller in size. Next I might tinker with an echo board & talkback. I wondered how i would identify the correct capacitor solders to remove. I ended up using a set of dividers to measure the center line of the cap then flip the radio over and found the solders.

The meter needle is stuck, but I've fixed those before. The 16ohm internal speaker was bad too, so replaced it with the only one that size I could find but it's an 8ohm. Ext spkr jack works as it should.

Attachments

Well, aside from that stuck meter, are you having more problems?

Or can I give you - by what you've posted - a couple of Atta' Boys! for you as well as a Kudos or two as well.

Nice to see you've got this - and I'd say you did well!

Looking over those photos, I'm glad to know that you managed to replace those caps, and as you've discovered, those caps can be considerably corrosive and very detrimental to the board as they age. By what I see, these caps were used in a wet or moist/high humidity environment. The Soldering pads themselves show some oxides like you'd get thru moisture and you see this in mobile setups - the morning dew drying off in the case - left alone can cause this discoloration and with sulfur as a main product of the Electrolyte - heat can acerbate the acidity present even in the venting of that cap under normal use thru time. Looks like carbon exhaust, but it is from the "venting" the gasses pressured inside.

Considering the expiration of the certificate I am glad to see you stuck this out and returned for an update!

Thank you.

You will have more work, but that is cleaning a details - like Potentiometer and Solder reheating and reseating of parts - careful with the Audio Chip - with what is being shown - the legs of the chip can "snap" so just re-heat and reflow the solder just to make sure you have your ducks in a row.

As far as the pots, I just use a deep well socket, 12mm or 11mm to remove locknut that holds down the pot. Gently remove it and place the hot tip of the soldering iron on the seat of the shaft where the ferrule meets the body - a bearing is in there...to reflow re-melt some of the old lube that may still be on the shaft - the reheat process can help with lessening the scratchy sound they add to the signal as you turn the knobs. So any help in preserving the original helps.

Or can I give you - by what you've posted - a couple of Atta' Boys! for you as well as a Kudos or two as well.

Nice to see you've got this - and I'd say you did well!

Looking over those photos, I'm glad to know that you managed to replace those caps, and as you've discovered, those caps can be considerably corrosive and very detrimental to the board as they age. By what I see, these caps were used in a wet or moist/high humidity environment. The Soldering pads themselves show some oxides like you'd get thru moisture and you see this in mobile setups - the morning dew drying off in the case - left alone can cause this discoloration and with sulfur as a main product of the Electrolyte - heat can acerbate the acidity present even in the venting of that cap under normal use thru time. Looks like carbon exhaust, but it is from the "venting" the gasses pressured inside.

Considering the expiration of the certificate I am glad to see you stuck this out and returned for an update!

Thank you.

You will have more work, but that is cleaning a details - like Potentiometer and Solder reheating and reseating of parts - careful with the Audio Chip - with what is being shown - the legs of the chip can "snap" so just re-heat and reflow the solder just to make sure you have your ducks in a row.

As far as the pots, I just use a deep well socket, 12mm or 11mm to remove locknut that holds down the pot. Gently remove it and place the hot tip of the soldering iron on the seat of the shaft where the ferrule meets the body - a bearing is in there...to reflow re-melt some of the old lube that may still be on the shaft - the reheat process can help with lessening the scratchy sound they add to the signal as you turn the knobs. So any help in preserving the original helps.

Next time you need caps...

https://www.worldwidedx.com/members/klondike-mike.13532/

https://www.worldwidedx.com/members/klondike-mike.13532/

dxChat

- No one is chatting at the moment.