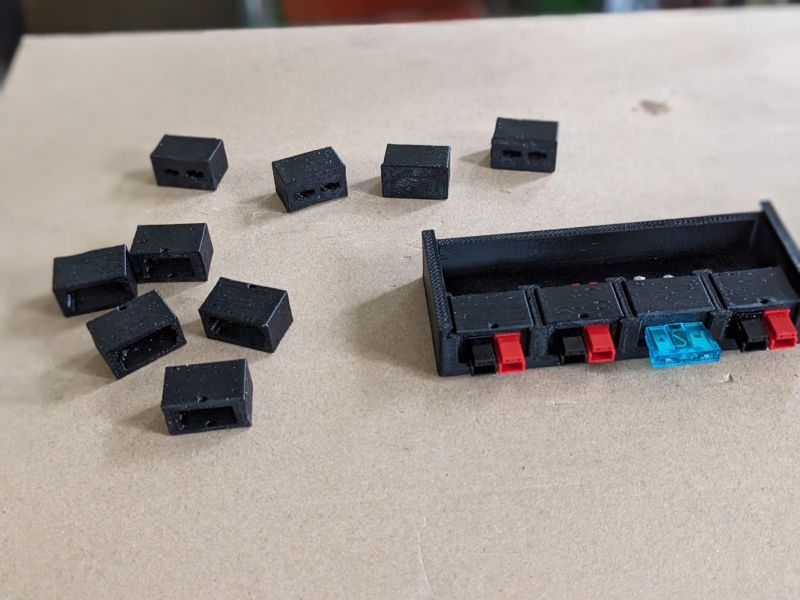

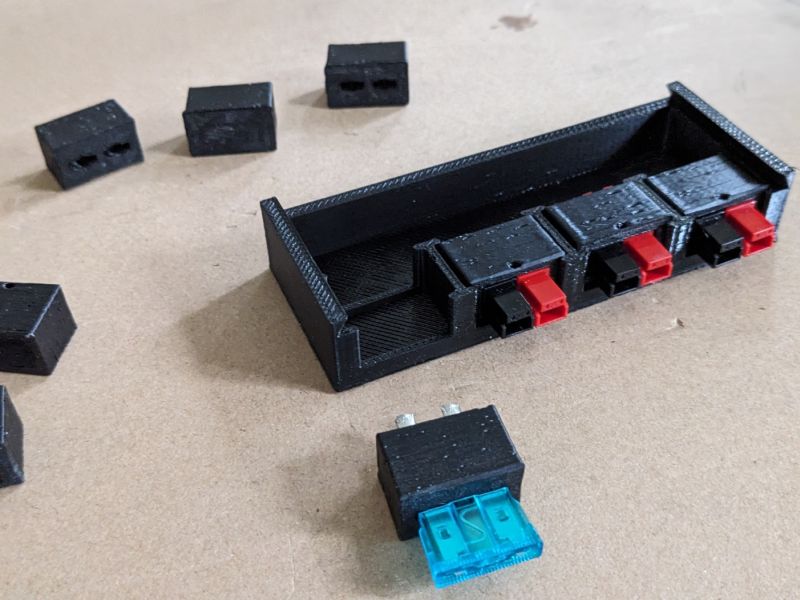

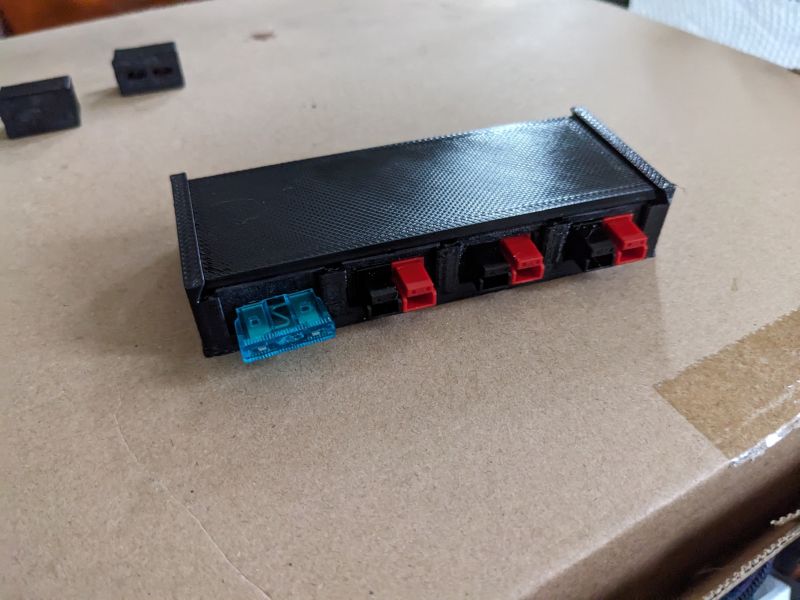

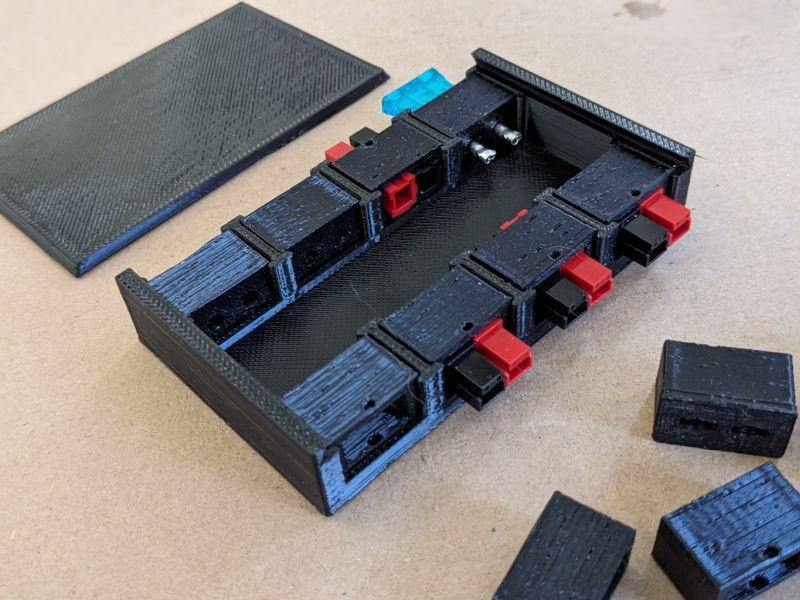

I just finished up a new version of components to build a 3D printed Anderson PowerPole distribution box. It differs from the previous versions I've done in that it has a flat profile and is modular. The basic housing framework has slots for "modules". There are modules for holding powerpole pairs, fuses (standard automotive) and blank placeholders. Customized versions can be assemblled that include fuses for some, all or none of the circuits. The housings can be either single sided or double sided. Once modules are in place in the slots, a slide lid is used to secure things in place. It can be secured with glue if desired.

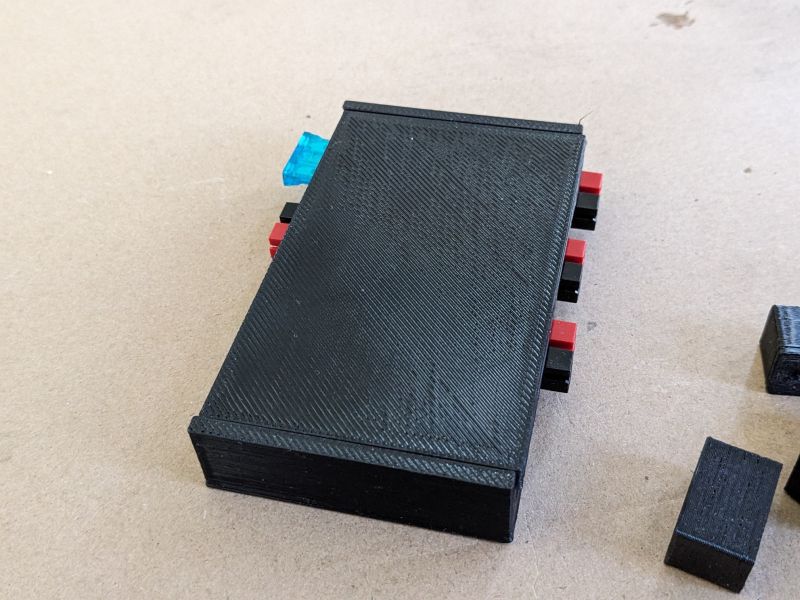

Pics of a 4 slot, single sided assembly:

Now pics of a double sided, 4 slot housing:

I put files on Printables for 4 & 6 slot, single & double sided versions. I also included the Fusion 360 source file. The Fusion 360 source file was parameterized so that changing the "circuit_n" parameter automaticly adjusts the single & double sided versions to include the specified number of slots per side and adjusts all related components to fit.

https://www.printables.com/model/816564-anderson-powerpole-modular-flat-distribution-box

Pics of a 4 slot, single sided assembly:

Now pics of a double sided, 4 slot housing:

I put files on Printables for 4 & 6 slot, single & double sided versions. I also included the Fusion 360 source file. The Fusion 360 source file was parameterized so that changing the "circuit_n" parameter automaticly adjusts the single & double sided versions to include the specified number of slots per side and adjusts all related components to fit.

https://www.printables.com/model/816564-anderson-powerpole-modular-flat-distribution-box