I deal with Low-Budget - Indie-type of installs...

They don't have the $$$ for ovens and kits or radios that survive nor the environment conducive for it - you have to look at the bigger picture.

Not many have resources available like some one us have been blessed with the knowledge on how to use and understand the process. They just want to get thru the day.

I just use a light bulb on a switch for cold mornings in mobiles - else Base radios - turn on the desk lamp and aim for the case, just let the thing warm up for about 5 minutes. Laugh if you want, but it works.

Heck, even a desk lamp shining down on the case of the radio can help remove the humidity effects and stabilize the parts and their compositions without have to "oven" the Xtal - which still doesn't fix the external controls. Those again are environmental effects affecting (the external) that which has some benefit of stability (the internal) - but is it worth the cost?

I'd rather have the radio act up in warm-up periods, for they are indicators of further problems getting worse. A noisy pot can be cleaned and re-lubed. But component failure? Although moot - at least by observation of the warm-up process, we can gather a lot of information alone in observing the symptoms - for one symptom may indicate a particular part, but is that the part that's is causing the problem? Not in all my experiences, hence the "shotgun" approach I take - not all symptoms are dealing with one part, there are many in the chain to choose from.

But with that out of the way...

I wanted to say, that out of all the drifting issues I have had some across my desk, the biggest culprits are...

Maximum slide - meaning the pot the operator turns, is the one that is "Volted" to buss and to ground with nothing in-between to stop it.

They never realize the effort of the Voltage divider circuit - the potentiometer is placed in the middle of, for the sake of linearity on the front panel control range.

It is so painful at times to see how some radios are so spaghetti-ed on the front panel, to bypass this and go here to get that approach, I've spent hours - if not days, undoing all of it to bring it back to stock, only to find out that somewhere along the way, putting it back to stock fixed the problem and the radios' acting normally again.

How do you charge a guy like that? By the hour? Or just give him a radio they can't do all of what they did to this one you just fixed? Sell the one you just fixed to someone else that will appreciate it for what it is and not mess with it - boy those days are fewer and fewer....if youtube is an indicator.

Anywhoo...

When you guys start talking about "tuning" and stability - there's always the variables yes, but, when the end user decides to "go for broke" - usually winds up making the radio "broke" because they exceeded limitations on voltages.

Varactors, for what they are - are wonderful devices but only exhibit their true reasons as to why we like them, thru a narrow range of voltage. They don't need much current, they're reverse biased so they simply act like a tuning capacitor when presented to a Crystal - which then reacts to that, and we gather that energy and put it elsewhere in the radio to use.

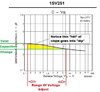

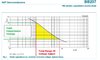

Here's what I'm talking about - a couple of charts some of you may recognized these so I won't bore you but to the rest - what I want you the curious one, to see is how much we have to apply to make the change in tuning that provides the range of band we can tune...

Look at the highlited in yellow areas, that is a tiny amount of capacitve change for a wide voltage range. The effort only gives you a small amount of capacitive reactance to make the series circuit with the crystal - change it's resonant frequency...

But, that's for Clarifier - we don't want or need a TON OF SLIDE if we were to just tune into someone within the channel itself - so that is why the level of change ratios are so vast compared to say...something you need a PLL to use...

It really hope all of you are caring to notice - the following...

The largest range of capacitance is in a small range of voltage - note the slope of this rate.

The greatest change in capacitance is when the voltage to it is less than - not more than, the effective SAFE OPERATIONAL AREA (SOA) of all the parts involved.

The Clarifier is a voltage divider - if we set other FIXED resistance above and below, we can effectively meet the maximum rate of change within a small range of voltage to achieve the adjust slide we want.

The best and most stable clarifiers use the smallest change of capacitance used in the entire range - helping to reduce drift.

PLL circuits can use the maximum rate of change in a small window to obtain their best stability AUTOMATICALLY thru their loops and phase detectors. So large value varactors give you the best ability of the PLL to maintain the frequency it is set to use.

So we need to quit making clarifiers with TONS of slide that get us into stability and warble troubles more than they're worth in slide - due to the constant changes we need to make as an operator to stay on frequency - it is our responsibility to keep us "dialed in" - no one wants to talk to some one that can't stay on frequency.

:+> Andy <+: