The Harbach board with the snap-in caps is what we have been using for a while now. No failures in the field yet. I do one thing to reduce twisting stress on the caps' solder connections to the pc board. We solder one pin only of each cap. Having the caps attached to the board makes it less clumsy to insert the board into the egg crate and then tighten down the mounting nuts. Any slight sideways skew will now be relieved when that one solder connection on each cap is first remelted with the iron. You might see one or more of the pins shift just slightly in the hole when you do this. Once that's done, it's time to solder the other pin of each capacitor. This way the solder has solidified with the pins in their "relaxed" position. No sideways pressure on the solder. Solder is not a good structural material. Any kind of 'spring' pressure on it can cause fatigue cracks to form in the solder fillet after a few hundred cycles of operating-temperature rise and fall.

A 5-Watt wirewound resistor is fine for R3 if you just want to replace that alone.

I like the W7RY board mainly because he uses stouter diodes for the zener replacement. Jeff's Harbach meter/HV board does a good job on sideband, but I don't recommend it for AM use.

The rectifier diodes on your original board are the 'small' type, and should probably be upgraded to the larger 1N5408 type used on both the Harbach and W7RY boards. The leads are thicker on that part. You would have to drill out the holes to simply upgrade your factory board to the larger rectifiers.

A new pc board would be my recommendation in light of that.

Your HV transformer passed the 'ground one side' test. Just say prayer for it every night before bedtime.

Could be that the transformer's actual breakdown voltage is just a little higher than what your line voltage puts onto it. If it deteriorates, and that threshold comes down after a while, it will pop R3 again later on down the line. This is where putting 3500 Volts DC onto the red and red/yellow wires with a tester can improve your confidence in the transformer's expected life span.

But for now it looks as if you're okay to rehab this one and put it on the air.

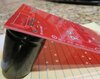

Sure is a clean specimen. That's usually a good sign.

73