Thanks. I go back to work tomorrow for four days and then off for four days. Repeat ad nausem. Going to try and start on things soon. I took a tube socket all apart earlier today to take to work tomorrow and give it a chemical bath and a good high pressure washing before taking the silver polish too it. Also taking two blower cages to sand blast and clean up. Lots of little stuff to get ready including polishing the meters to get rid of some tiny scratches. I may start drilling holes to mount power supply components next week. I also need to made tie-downs for the filter caps so there is certainly no shortage of little details to take care of.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

-

You can now help support WorldwideDX when you shop on Amazon at no additional cost to you! Simply follow this Shop on Amazon link first and a portion of any purchase is sent to WorldwideDX to help with site costs.

-

The Retevis Holidays giveaway winner has been selected! Check Here to see who won!

I was bored today.

- Thread starter Captain Kilowatt

- Start date

The only holes that may present a headache are the holes for the meters. They will be mounted in a 1/8 inch thick aluminum panel and I may have them done at work on the milling machine. I have used a fly cutter on the drill press but that thick times six holes is more work than I want to get into.

Well it never rains but pours. I had planned to get a start on things last week but my kidney decided to create a stone

and that has had me preoccupied the last several days. I was supposed to work this past Tuesday before going on four days off again. Monday night was spent in the ER in shear agony. Lots of painkillers and tests later they found a stone too big to pass. It was lodged between the kidney and the bladder. I went home that night after spending about 12 hours in the local hospital. Got a call about noon the following day to go immediately to the city hospital to have it removed. That was both exciting to hear and daunting at the same time. Finally got home late Wednesday evening and have just been resting since then. The stent comes out tomorrow. Another day of mixed emotions.

and that has had me preoccupied the last several days. I was supposed to work this past Tuesday before going on four days off again. Monday night was spent in the ER in shear agony. Lots of painkillers and tests later they found a stone too big to pass. It was lodged between the kidney and the bladder. I went home that night after spending about 12 hours in the local hospital. Got a call about noon the following day to go immediately to the city hospital to have it removed. That was both exciting to hear and daunting at the same time. Finally got home late Wednesday evening and have just been resting since then. The stent comes out tomorrow. Another day of mixed emotions.

Oh yeah......when they did the initial bloodwork when I went to hospital they determined I am a type 2 diabetic. Lots of wonderful news this week. Back to work on Sunday on light duty for a couple days and then hopefully when I am off again starting on next Thursday I can get a start on at least the little things.

Oh yeah......when they did the initial bloodwork when I went to hospital they determined I am a type 2 diabetic. Lots of wonderful news this week. Back to work on Sunday on light duty for a couple days and then hopefully when I am off again starting on next Thursday I can get a start on at least the little things.

My wife and I wish you the very best! My wife has now had 2 transplants and has done hemo dialysis 2 1/2 years the first time and 12 years the secound time before transplant. Please be well, take it easy on foods high in potassium, salt, and drink lots of water and cranberry juice. Dialysis sucks....My wife knows, ans I did her Hemo its hard but better at home then at a center.Well it never rains but pours. I had planned to get a start on things last week but my kidney decided to create a stoneand that has had me preoccupied the last several days. I was supposed to work this past Tuesday before going on four days off again. Monday night was spent in the ER in shear agony. Lots of painkillers and tests later they found a stone too big to pass. It was lodged between the kidney and the bladder. I went home that night after spending about 12 hours in the local hospital. Got a call about noon the following day to go immediately to the city hospital to have it removed. That was both exciting to hear and daunting at the same time. Finally got home late Wednesday evening and have just been resting since then. The stent comes out tomorrow. Another day of mixed emotions.

Oh yeah......when they did the initial bloodwork when I went to hospital they determined I am a type 2 diabetic. Lots of wonderful news this week. Back to work on Sunday on light duty for a couple days and then hopefully when I am off again starting on next Thursday I can get a start on at least the little things.

You are in our prayers, and prayer list at church.

That one reminds me of when I learned that LMR 400 wasn't the end all sweetness I thought it was. Tuning my little toy at the time to see how much I could get with a monster transformer I found. Hit between 3k and 4k and totally fried the coax end, PL, and SO all in a couple seconds. Fun stuff.Oh crap......this means I may have to upgrade some pieces of feedline eventually when things are done. Not sure I want to trust foam dielectric RG-8. It's only rated for 300 volts and that's only 1800 watts. My legal limit is 2250 pep or a full 750 watt carrier on AM plus 100% modulation for a peak power of 3000 watts on AM mode.

Good luck with both the recovery and the project.

All my main runs of cable are Andrews LDF4-50 half inch heliax so that is not an issue in the slightest however I will have several short jumpers in the run like from the shack to the basement, into and out of lightning surge suppressors, and from the remote coaxial switch and up around the rotator to the antennas.

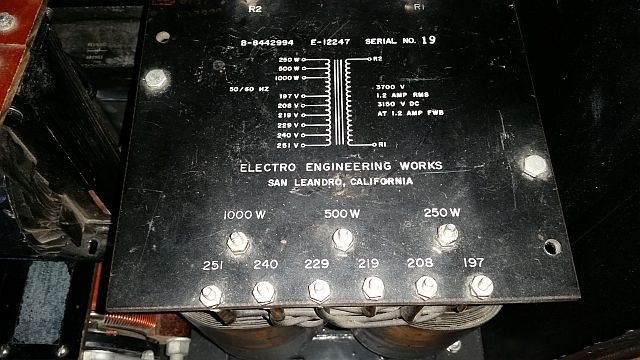

A discussion in another thread prompted me to revisit this one. The project has seen some progress but it has been on the back burner since early last spring and it is time to continue it. This is the plate transformer. The 220 volt primary connects between the 251 volt terminal (my normal line voltage is near 250 volts) and one of the other terminals labeled 250, 500, 0r 1000 watts. This selects the output voltage. The secondary remains untapped.

Basic layout of the HV section. The plate xmfr is of course on the right and the 30 amp variac on the right will control the primary voltage to the HV section. Behind that are the filter capacitors which are oil filled non-PCB type offering 55 uF.

Better view of the filter caps. The HV rectifiers are mounted on a shelf above the caps.

The business end of the power supply. The three relays from right to left are for main primary power to the filaments and blower, primary to the plate transformer, and the third relay is for bypassing the series current limiting resistors that are in the plate transformer primary leads. The yellow box on the left side is a solid state timer relay that controls the time delay for switching the step start circuit. On the far right is a 30 amp Corcom line filter just because I had one and to reduce any RF feeding back onto the AC lines. Old style ceramic fuse holder is mounted on the right and a transformer for low voltage control relays and indicators is on the left wall. the rectifiers are under the relay shelf.

Basic layout of the HV section. The plate xmfr is of course on the right and the 30 amp variac on the right will control the primary voltage to the HV section. Behind that are the filter capacitors which are oil filled non-PCB type offering 55 uF.

Better view of the filter caps. The HV rectifiers are mounted on a shelf above the caps.

The business end of the power supply. The three relays from right to left are for main primary power to the filaments and blower, primary to the plate transformer, and the third relay is for bypassing the series current limiting resistors that are in the plate transformer primary leads. The yellow box on the left side is a solid state timer relay that controls the time delay for switching the step start circuit. On the far right is a 30 amp Corcom line filter just because I had one and to reduce any RF feeding back onto the AC lines. Old style ceramic fuse holder is mounted on the right and a transformer for low voltage control relays and indicators is on the left wall. the rectifiers are under the relay shelf.

Added the filament transformer in the top left. It is mounted above a second variac to allow precise adjustment of the filament voltage. I was going to use a high power ceramic pot I had which is normally used in transmitters however this will allow a better range of adjustment and is more efficient. It is also a lot heavier too. LOL

Overall view of the back so far. The rack is a four foot high Hammond and does have a hinged door that was removed for ease of working on it.

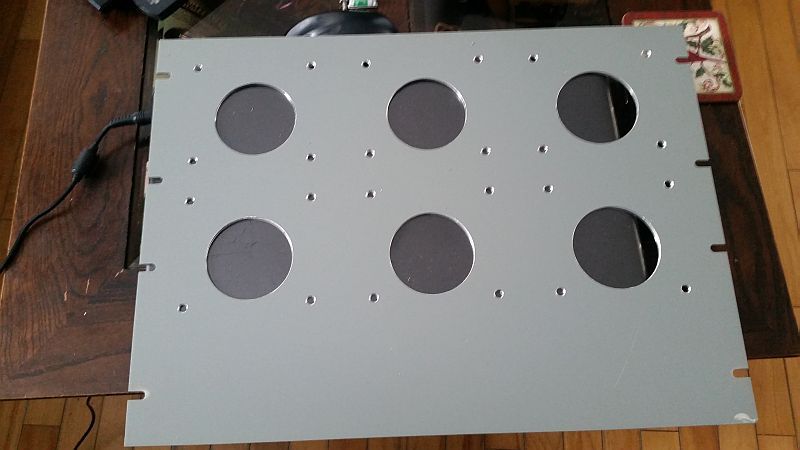

Front view before any holes are drilled.

Meter panel. It turned out better than I thought. I used a new 2 3/4 inch hole saw for metal and use the lowest speed possible on the drill press.

Finished meter panel.

Overall front so far. The bottom variac is for the HV while the top one is for the filaments. The HV primary cannot be engaged unless the filament/blower supply is turned on first. The filament supply is run thru an air vane switch so that if the blower should fail the filament supply and also the plate supply will be switched off to protect the tube. this basically as far as I got last spring. The next step is to incorporate the main power switches and then start to construct the RF cabinet for the tube which will be right above the power supply and the tank circuit will be above that. With a little luck it will all fit in but will require attention to detail and some creative gear linkages between the turns counters and the capacitor shafts. I may end up lowering the meter panel to the middle in front of the RF cabinet and mount the tank circuit at the top with straight thru shafts. as a note the total weight so far is up to 218 pounds and the RF tube and cabinet and tank circuit have yet to be installed.

Overall view of the back so far. The rack is a four foot high Hammond and does have a hinged door that was removed for ease of working on it.

Front view before any holes are drilled.

Meter panel. It turned out better than I thought. I used a new 2 3/4 inch hole saw for metal and use the lowest speed possible on the drill press.

Finished meter panel.

Overall front so far. The bottom variac is for the HV while the top one is for the filaments. The HV primary cannot be engaged unless the filament/blower supply is turned on first. The filament supply is run thru an air vane switch so that if the blower should fail the filament supply and also the plate supply will be switched off to protect the tube. this basically as far as I got last spring. The next step is to incorporate the main power switches and then start to construct the RF cabinet for the tube which will be right above the power supply and the tank circuit will be above that. With a little luck it will all fit in but will require attention to detail and some creative gear linkages between the turns counters and the capacitor shafts. I may end up lowering the meter panel to the middle in front of the RF cabinet and mount the tank circuit at the top with straight thru shafts. as a note the total weight so far is up to 218 pounds and the RF tube and cabinet and tank circuit have yet to be installed.

What is that?

I guess you didn't read the whole thread. Go on....take a guess what it is.

I guess you didn't read the whole thread. Go on....take a guess what it is.Hint: I mentioned the TUBE and RF cabinet.

Maco 750 on steroids?

For 6 metres, the East coast Canada way.Maco 750 on steroids?

Maco 750 on steroids?

Right church wrong pew.

It's a home built HF amp for 1.8-30 MHz. continuous. It will use a 3CX3000A7 ceramic tube which will eat a Maco-750 for breakfast and still be hungry.