Kris 600 SSB Update

Today was a productive day.

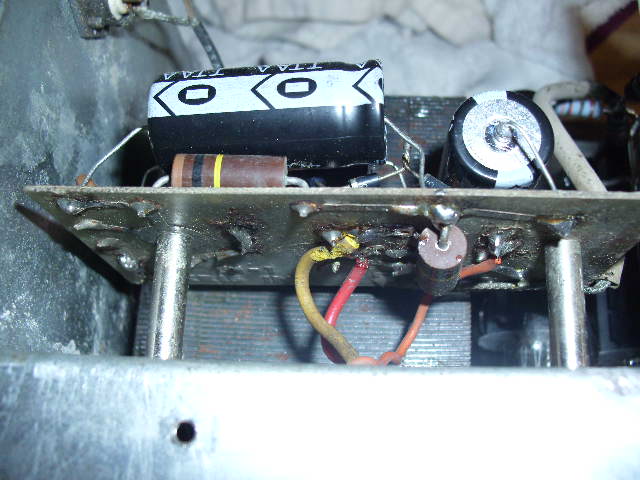

Medium Voltage power supply was rebuilt.

From this:

To this:

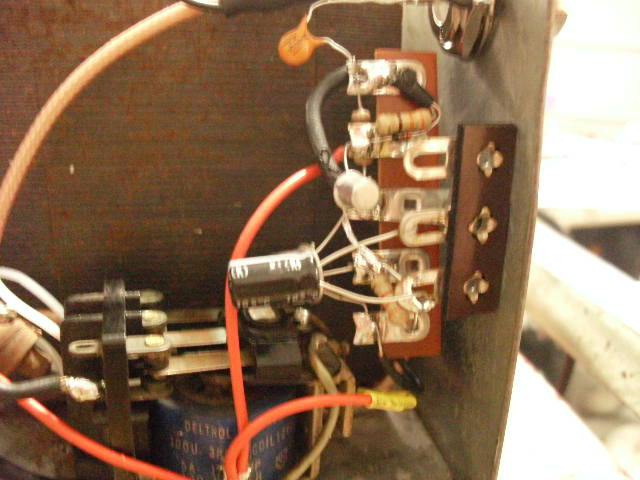

The High Voltage supply was finished. Filter capacitors and bleeder resistors replaced.

From this:

To this:

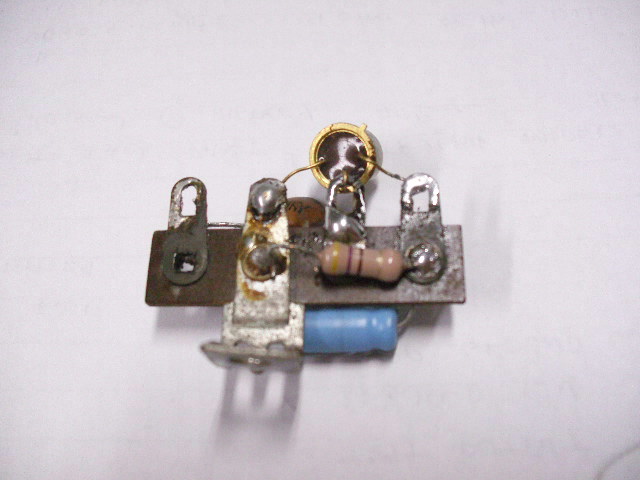

The replacement keying circuit was finished.

From this:

To this:

The keying circuit was built using the schematic of the Kris Big Boomer. It is very sensitive and will key with a little less than 1 watt. It did handle a 20 watt input just fine. The electrolytic "sticking out like a sore thumb" is the drop out Cap for the relay. It was left that way so that the owner could change it relatively easily if he desires for SSB. (This unit does not have an AM/SSB switch.)

A new fan was installed today as well. The original fan rattled and started very slowly. After running a couple minutes it finally got to full speed. When at full speed it was a vibrating mess! Not worth the effort to try to repair it when this replacement was $6.00 new!

The amp works showing about 125 watts output with 2 watts in on AM and roughly 250 watts modulated but the input match is not great. It shows about 2.5-3.0:1 when keyed. Not great is an understatement-it is terrible!

The Driver air variable is not meshed at all for full output and there is no trimmer for input matching/tuning on the driver tube. The Tune and Load air variables are about 1/2 to 2/3 meshed for full output. (Bad driver tube???)

Still left to do-

Solve the poor input tuning SWR (I'm open for suggestions here!)

Install a resettable circuit breaker on the rear panel (owners request)

Install the MOV's on the AC line cord

Install a Fast Blow fuse on the transformer high voltage winding output to the bridge rectifier

73's

David

Today was a productive day.

Medium Voltage power supply was rebuilt.

From this:

To this:

The High Voltage supply was finished. Filter capacitors and bleeder resistors replaced.

From this:

To this:

The replacement keying circuit was finished.

From this:

To this:

The keying circuit was built using the schematic of the Kris Big Boomer. It is very sensitive and will key with a little less than 1 watt. It did handle a 20 watt input just fine. The electrolytic "sticking out like a sore thumb" is the drop out Cap for the relay. It was left that way so that the owner could change it relatively easily if he desires for SSB. (This unit does not have an AM/SSB switch.)

A new fan was installed today as well. The original fan rattled and started very slowly. After running a couple minutes it finally got to full speed. When at full speed it was a vibrating mess! Not worth the effort to try to repair it when this replacement was $6.00 new!

The amp works showing about 125 watts output with 2 watts in on AM and roughly 250 watts modulated but the input match is not great. It shows about 2.5-3.0:1 when keyed. Not great is an understatement-it is terrible!

The Driver air variable is not meshed at all for full output and there is no trimmer for input matching/tuning on the driver tube. The Tune and Load air variables are about 1/2 to 2/3 meshed for full output. (Bad driver tube???)

Still left to do-

Solve the poor input tuning SWR (I'm open for suggestions here!)

Install a resettable circuit breaker on the rear panel (owners request)

Install the MOV's on the AC line cord

Install a Fast Blow fuse on the transformer high voltage winding output to the bridge rectifier

73's

David