You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

-

You can now help support WorldwideDX when you shop on Amazon at no additional cost to you! Simply follow this Shop on Amazon link first and a portion of any purchase is sent to WorldwideDX to help with site costs.

Palomar 300A Unicorn

- Thread starter 357

- Start date

OK found another tank coil similar.

Looks like people or the FCC starting crying because it didn't really work on 40m or something. Guess they were cheaping out and not using tinned wire after April 1977

I dont think they even used ferrite parasitics on the finals either then.

Maybe that was around the end of the line?

not sure

Looks like people or the FCC starting crying because it didn't really work on 40m or something. Guess they were cheaping out and not using tinned wire after April 1977

I dont think they even used ferrite parasitics on the finals either then.

Maybe that was around the end of the line?

not sure

Pins 3 and 11 is the screen grid. I know on some of the Palomar tube mobile amps they put +12 volts on the screen grid to give the tubes a little more gain. They might have done the same on some of the 300A's to beef up the peak power a little on the driver section.

It especially helps if there is only 700-750 volts on the plate. Some sweep tube amps have 900+ volts on the plate but I've seen 300A's with less than 800 volts.

It especially helps if there is only 700-750 volts on the plate. Some sweep tube amps have 900+ volts on the plate but I've seen 300A's with less than 800 volts.

I dont think they even used ferrite parasitics on the finals either then.

They did. But as soon as the amplifier got run on high side for a while they would get hot, crack in half and pile up on the bottom cover.

Until the first time the bottom was removed. Then they're gone forever without a trace. Haven't found those rattling around in the bottom of a 300A in a very long time.

Sure would like to see a proper sequence of the engineering changes as they progressed.

Oldest ones had the tube sockets mounted to the metal chassis. That didn't last long, and the more-familiar circuit boards were where the tube sockets went, mounted on plastic spacers that get hot and shrink.

Older versions had an open-frame single-pole relay in line with the B+, mounted on the pcb with the HV filter caps. Then it got moved to the chassis behind the standby switch.

And then it went away forever. Used switched grid bias to put the tubes on standby after that.

Three relays mounted on the plug-in circuit board got changed around 1974 or 1975 to a soldered-in pc board with the antenna relay in a socket, located beneath the Load control. This version had the two R50 sealed relays that always go bad.

The factory schematic shows no separate input-matching circuit for Low side. But nearly all of the amplifiers I have seen include this coil and cap mounted to the rear of the High/Low switch.

The band coils definitely saw some revision, as the pics above demonstrate. We learned the hard way to remove the driver tank coil altogether and replace it with 5 turns of #12 wire.

Only the screen grids on the driver tubes got the positive voltage fed to them. This created a hazard to the 12-Volt circuits any time a driver tube got too hot and flashed over inside.

Like most manufactured products, the design would change every time they built another batch.

73

Last edited:

They did. But as soon as the amplifier got run on high side for a while they would get hot, crack in half and pile up on the bottom cover.

Until the first time the bottom was removed. Then they're gone forever without a trace. Haven't found those rattling around in the bottom of a 300A in a very long time.

Sure would like to see a proper sequence of the engineering changes as they progressed.

Oldest ones had the tube sockets mounted to the metal chassis. That didn't last long, and the more-familiar circuit boards were where the tube sockets went, mounted on plastic spacers that get hot and shrink.

Older versions had an open-frame single-pole relay in line with the B+, mounted on the pcb with the HV filter caps. Then it got moved to the chassis behind the standby switch.

And then it went away forever. Used switched grid bias to put the tubes on standby after that.

Three relays mounted on the plug-in circuit board got changed around 1974 or 1975 to a soldered-in pc board with the antenna relay in a socket, located beneath the Load control. This version had the two R50 sealed relays that always go bad.

The factory schematic shows no separate input-matching circuit for Low side. But nearly all of the amplifiers I have seen include this coil and cap mounted to the rear of the High/Low switch.

The band coils definitely saw some revision, as the pics above demonstrate. We learned the hard way to remove the driver tank coil altogether and replace it with 5 turns of #12 wire.

Only the screen grids on the driver tubes got the positive voltage fed to them. This created a hazard to the 12-Volt circuits any time a driver tube got too hot and flashed over inside.

Like most manufactured products, the design would change every time they built another batch.

73

Is it possible to burn the tubes in with the HV disconnected?

Will it make the cathode run away?

I'd like to run the heaters for a day. All the tubes test NOS in mine. I'd hate to see them flash over

Running it on standby with the plate-cap clips unhooked should not hurt anything.

Unless you accidentally brush your elbow up against one of them.

73

Unless you accidentally brush your elbow up against one of them.

73

ok thanks.Running it on standby with the plate-cap clips unhooked should not hurt anything.

Unless you accidentally brush your elbow up against one of them.

73

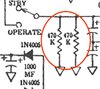

I forgot to grab 470K resistors for the HV bleeders. they have two 470K to make around 220K

Would one 5w 100K be ok? I knew I forgot something.

the originals are measuring 650K each

Could I go 100K 3W on the original spot and another 100K 3W from the middle of the 3 capacitors to ground or would that mess up the doubler? I also have 100K 5W if necessary

Thanks

Last edited:

One resistor in parallel with one capacitor.

Each.

The drawing that joins the midpoint of the two caps in series to the midpoint of the two resistors in series is the right one.

This just works better. The factory's setup was bogus.

73

Each.

The drawing that joins the midpoint of the two caps in series to the midpoint of the two resistors in series is the right one.

This just works better. The factory's setup was bogus.

73

thank you sir!One resistor in parallel with one capacitor.

Each.

The drawing that joins the midpoint of the two caps in series to the midpoint of the two resistors in series is the right one.

This just works better. The factory's setup was bogus.

73

completion pics otw