For the Stryker 955. All bullsh*t hype, or is there some validity to it's use? ... other than dissipating a bit more heat?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

-

You can now help support WorldwideDX when you shop on Amazon at no additional cost to you! Simply follow this Shop on Amazon link first and a portion of any purchase is sent to WorldwideDX to help with site costs.

Palomar Max Mod

- Thread starter Greg T

- Start date

B$

Mike

Kinda what I was thinking, since "Mark" is pushing the hell out of them. The only advantage I see is the larger foot print to dissipate heat

If you want better heat transfer, trash ceramic insulator and use mica.

Want better transistor use BD250C, TIP35 or similar. 25A continuous, 125W, will last forever.

Their junction temperature is up to 302F so as long as there is no burn on your finger, there is nothing to worry about.

Want better transistor use BD250C, TIP35 or similar. 25A continuous, 125W, will last forever.

Their junction temperature is up to 302F so as long as there is no burn on your finger, there is nothing to worry about.

Last edited:

If you want better heat transfer, trash ceramic insulator and use mica.

Want better transistor use BD250C, TIP35 or similar. 25A, 125W, will last forever.

I don't really think anything is necessary. I just saw so much hype on the things I was wondering how much was true. Looks like an extremely simple mod IF it was worth it. I never push a radio hard anyway, so I don't see a reason to change it

Me neither.I don't really think anything is necessary.

Mike

The only advantage I see is the larger foot print to dissipate heat

Thats all relative, especially when relatives are arriving...

Might want to pre-heat the fins in the back of that radio to help provide the extra cooking surfaces needed to handle the heat the guests will demand from the kitchen.

The TO-220 package is not a one size fits all heat exchanger, follow @sp5it advice and just use the TO-3P (TO-247 for "modernizing") and the 25A surge thru those copper foil traces will certainly start a small fire - perfect for camping and testing the batteries in smoke alarms...

If you ever wanted Chaos...

@Crawdad7 - thank you for bringing this up.

Now, I'll save you the rest of the story - at least the hour watching the rest of the video you can cringe at that later. The part at 14:30 to 15:15 is where these two shots come from the PIP (Pic in Pic) showing he uses a simple screwdriver flat blade to pry up and off the parts and the ceramics are also breaking at this same time.

Wanted to suggest to @Greg T it's not just getting a TIP36C - but a proper insulator too.

Call me old school but I find the MICA (transparent thin wafer) is what I like - as long as the surface it's to mount to is also done in a fashion to remove burrs and defects - dirt - shards - chips and smooth out any dent's dings or curves in the mating surface.

If you watch the vid - the process goes pretty fast and doesn't show all his prep for the Max mod part - being the largest of any replacements (I cannot call it a rebuild - nothing was broken) So you have to take the ball and run with it, that being you need to make sure the mounting flange, and spreader surface are flat - no deformations in the epoxy to flange surfaces that can lift the surface from the spreader meant to carry the heat away.

The main premise here is to use the right materials and products - you will have to use your own judgement. But what I find so harsh is; the ease in how in the vid - the buck-gets-passed back to the maker Qixiang (like Really?) - even quips about asking for more of these insulators.

So, since this was a thread more based upon "Since you asked" - well, I have to leave this with you. For you know your customer, and wipe that sweat off your brow, it's not that bad...

The thinner insulators of natural materials (Mica - in this case) is the better choice for mating with a flat metal surface with little capacity for latency heat dissipation. Meaning the spreader, what it's bolted to, is thinner that the die mount plate the part has for itself. So since one of steel and the other of Aluminum - the choices are few - Mica versus Ceramics - the Mica works better for me in carrying the heat away and resists "fracking" caused by overzealous screwdriver tips.

The goo is another - find and use "white" not the grey. And must be pure insulator - try to avoid zinc pastes which conduct and will put you right back into what I mentioned in the VID - cracking - penetration and perforation failure.

Wash your parts before reassembly - in alcohol - to remove the old paste and also help in align and proper seating - don't solder in the part until you have it mounted firmly enough and not distorted to the case or the tab folding back or inwards due to the warp the case exhibits.

Once soldered in, you should not have to retighten it, that grounds for failure right there.

Now, I'll save you the rest of the story - at least the hour watching the rest of the video you can cringe at that later. The part at 14:30 to 15:15 is where these two shots come from the PIP (Pic in Pic) showing he uses a simple screwdriver flat blade to pry up and off the parts and the ceramics are also breaking at this same time.

Wanted to suggest to @Greg T it's not just getting a TIP36C - but a proper insulator too.

Call me old school but I find the MICA (transparent thin wafer) is what I like - as long as the surface it's to mount to is also done in a fashion to remove burrs and defects - dirt - shards - chips and smooth out any dent's dings or curves in the mating surface.

If you watch the vid - the process goes pretty fast and doesn't show all his prep for the Max mod part - being the largest of any replacements (I cannot call it a rebuild - nothing was broken) So you have to take the ball and run with it, that being you need to make sure the mounting flange, and spreader surface are flat - no deformations in the epoxy to flange surfaces that can lift the surface from the spreader meant to carry the heat away.

The main premise here is to use the right materials and products - you will have to use your own judgement. But what I find so harsh is; the ease in how in the vid - the buck-gets-passed back to the maker Qixiang (like Really?) - even quips about asking for more of these insulators.

- Think about this...

- Why did he ask that radio maker for the very same parts he's complaining that fail?

- Go review the vid, start about 14Min mark for that and decide that for yourself.

So, since this was a thread more based upon "Since you asked" - well, I have to leave this with you. For you know your customer, and wipe that sweat off your brow, it's not that bad...

The thinner insulators of natural materials (Mica - in this case) is the better choice for mating with a flat metal surface with little capacity for latency heat dissipation. Meaning the spreader, what it's bolted to, is thinner that the die mount plate the part has for itself. So since one of steel and the other of Aluminum - the choices are few - Mica versus Ceramics - the Mica works better for me in carrying the heat away and resists "fracking" caused by overzealous screwdriver tips.

The goo is another - find and use "white" not the grey. And must be pure insulator - try to avoid zinc pastes which conduct and will put you right back into what I mentioned in the VID - cracking - penetration and perforation failure.

Wash your parts before reassembly - in alcohol - to remove the old paste and also help in align and proper seating - don't solder in the part until you have it mounted firmly enough and not distorted to the case or the tab folding back or inwards due to the warp the case exhibits.

- Don't overdo - the goo...

- - in this case LESS is More (Better - SIGH)

- Because of the "sticky" viscosity and aggressively tacky behavior of the goo, a little goes a long way, and you don't want to make it an attractant for Lint, Dust Bunnies and Hairs you don't have a clue where they came from - collecting in, on and around it.

Once soldered in, you should not have to retighten it, that grounds for failure right there.

Last edited:

This kinda fits in with the topic. I received the 955 today and got the conversion done, and set the levels where I needed them. But, I noticed the internal volt meter sits at idle voltage and matches my PSU setting perfectly, until I transmit. during TX the internal meter drops to 13.3 or 13.4V . Shouldn't the regulator keep it at 13.8 or so? Not that I think it's a big deal, but just curious. I keep my PSU at 14.1V and it drops to 14.0 during TX, so there should be plenty of food in the pipe to run it.

@Crawdad7 - thank you for bringing this up.

Now, I'll save you the rest of the story - at least the hour watching the rest of the video you can cringe at that later. The part at 14:30 to 15:15 is where these two shots come from the PIP (Pic in Pic) showing he uses a simple screwdriver flat blade to pry up and off the parts and the ceramics are also breaking at this same time.

Wanted to suggest to @Greg T it's not just getting a TIP36C - but a proper insulator too.

Call me old school but I find the MICA (transparent thin wafer) is what I like - as long as the surface it's to mount to is also done in a fashion to remove burrs and defects - dirt - shards - chips and smooth out any dent's dings or curves in the mating surface.

If you watch the vid - the process goes pretty fast and doesn't show all his prep for the Max mod part - being the largest of any replacements (I cannot call it a rebuild - nothing was broken) So you have to take the ball and run with it, that being you need to make sure the mounting flange, and spreader surface are flat - no deformations in the epoxy to flange surfaces that can lift the surface from the spreader meant to carry the heat away.

The main premise here is to use the right materials and products - you will have to use your own judgement. But what I find so harsh is; the ease in how in the vid - the buck-gets-passed back to the maker Qixiang (like Really?) - even quips about asking for more of these insulators.

This is why I have such an axe to grind...was it necessary - really needed? Because for one to operate a shop in this fashion - puts the rest of us in a stereotypical spotlight you don't want to be shined on with...

View attachment 56922

It's lonely at the top...

So, since this was a thread more based upon "Since you asked" - well, I have to leave this with you. For you know your customer, and wipe that sweat off your brow, it's not that bad...

The thinner insulators of natural materials (Mica - in this case) is the better choice for mating with a flat metal surface with little capacity for latency heat dissipation. Meaning the spreader, what it's bolted to, is thinner that the die mount plate the part has for itself. So since one of steel and the other of Aluminum - the choices are few - Mica versus Ceramics - the Mica works better for me in carrying the heat away and resists "fracking" caused by overzealous screwdriver tips.

The goo is another - find and use "white" not the grey. And must be pure insulator - try to avoid zinc pastes which conduct and will put you right back into what I mentioned in the VID - cracking - penetration and perforation failure.

Wash your parts before reassembly - in alcohol - to remove the old paste and also help in align and proper seating - don't solder in the part until you have it mounted firmly enough and not distorted to the case or the tab folding back or inwards due to the warp the case exhibits.

- Don't overdo - the goo...

- - in this case LESS is More (Better - SIGH)

- Because of the "sticky" viscosity and aggressively tacky behavior of the goo, a little goes a long way, and you don't want to make it an attractant for Lint, Dust Bunnies and Hairs you don't have a clue where they came from - collecting in, on and around it.

Once soldered in, you should not have to retighten it, that grounds for failure right there.

- YouTube

Enjoy the videos and music you love, upload original content, and share it all with friends, family, and the world on YouTube.

Good observation @Greg T - because this shows why Bipolar versus MOSFET and their traits, continue to cause arguments reverberating thru the halls of Radio ...

Dealing with what some call "siemens" or capital S - an Ohmic (er - more micro- ohmic mho - archaic) measurement of resistance (or impedance) across a junction that generates the voltage drop and hence the loss you see in dip when you put the radio in Transmit.

The differences in linear operation in this such small region of measurement is what makes or breaks radios and power amps into sub-categories of Big Dogs, and Little Ducks - also referred to Mud - Ducks and Woofers...

IN bipolar days you have the Base and Emitter - losses (Drop) - compared to the Gate non-contact - to - substrate Impedance (Extremely High) so the ability of the part can handle the power is no longer dependent on the junctions of Collector to Base - Base to Emitter - being 3 different points with two distinct junctions and their intrinsically made voltage drops- so they took the BASE out of the question and made it a Gate and designed the substrate to act like a switch - a very good switch.

No, if you don't understand the graph - it's not necessary - but another might need it to compare the OUTPUT (Pink region) of the Source to Drain as your actual "knee" like you'd see in a bipolar - only in the Bipolar - you BIAS with Current - in MOSFET - you BIAS with Voltage

In the above example - the pink region is where the green line works with both VOLTAGE and CURRENT - of the GATE to force the Drain to Source ohmic Siemens to fluctuate until it's "fully on" - referencing the Siemens region the actual ohmic end result and power losses of the part being on.

So when those babies feeling off the milk from the bipolar-ized AM Regulator - they can flat suck the pipes dry from their demands - simply by the low-ohmic (S) characteristics they exhibit when they turn on - they turn on too well.

Dealing with what some call "siemens" or capital S - an Ohmic (er - more micro- ohmic mho - archaic) measurement of resistance (or impedance) across a junction that generates the voltage drop and hence the loss you see in dip when you put the radio in Transmit.

The differences in linear operation in this such small region of measurement is what makes or breaks radios and power amps into sub-categories of Big Dogs, and Little Ducks - also referred to Mud - Ducks and Woofers...

IN bipolar days you have the Base and Emitter - losses (Drop) - compared to the Gate non-contact - to - substrate Impedance (Extremely High) so the ability of the part can handle the power is no longer dependent on the junctions of Collector to Base - Base to Emitter - being 3 different points with two distinct junctions and their intrinsically made voltage drops- so they took the BASE out of the question and made it a Gate and designed the substrate to act like a switch - a very good switch.

Which generates its own problems of locating (finding) an operational point for linear operation for power flow by using a non-linear region of the Gate to substrate interaction threshold (Miller Effect) and make it work like their older bipolar ones - only you can't make the gate act like a Base - because it doesn't connect to anything - just provides a field.

No, if you don't understand the graph - it's not necessary - but another might need it to compare the OUTPUT (Pink region) of the Source to Drain as your actual "knee" like you'd see in a bipolar - only in the Bipolar - you BIAS with Current - in MOSFET - you BIAS with Voltage

In the above example - the pink region is where the green line works with both VOLTAGE and CURRENT - of the GATE to force the Drain to Source ohmic Siemens to fluctuate until it's "fully on" - referencing the Siemens region the actual ohmic end result and power losses of the part being on.

So when those babies feeling off the milk from the bipolar-ized AM Regulator - they can flat suck the pipes dry from their demands - simply by the low-ohmic (S) characteristics they exhibit when they turn on - they turn on too well.

Last edited:

So, basically a regulator is not really a regulator, but rather, a limiter. A true regulator would open up as necessary to maintain a certain designated voltage as demand increases. The fact that it drops to 13.3V or 13.4V under load shows that it limits maximum voltage but doesn't make up for a deficit under demand. Still, one would think the voltage would stay steady when the supply voltage is STILL 14.0V.

er, no - sigh I didn't do this well enough...

I guess when you look at this as a "regulator" remember the Regulator is trying to limit voltage - but supply a level of current so the "linear" in the regulation part is supposed to supply all the power that is needed - at that voltage.

The AM Regulator is unable to be a Constant Current Source unless you have the Genie in the Bottle. Right now, that's not possible - even with MOSFET designs - in regard to efficiency.

The "Siemens" factor proves that you cannot make the Bipolar a true constant current source because of the limits within the intrinsic layers - the junctions themselves.

MOSFET pulls power and abuses those stats - and is why some more popular amps that use Bipolar for their stages, pop their "pills" due to the ability of the MOSFET to be more efficient in showing low-Siemens (mho factor) at any point of is D-2-S linear slope - and gobbles up the current present at that voltage - readily. which shoves considerable amounts of power from wildly swinging output of a limter-less radio into the amp.

A TO-220 will "starve" and lose in the battle, but to control the losses you'll need a part that places more current within the traces feeing these. A TIP36C (or any selected 25A rated) in a TO-247 package. Leaving the TIP36 (recommended) in a bad position of having to supply more current at that voltage - than the Bipolar TO-220 ever could.

But while I got you here,

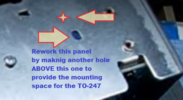

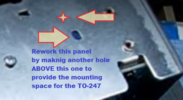

Your part you're putting in,

requires a rework that DOES violate a Warranty....

The TO-247 needs a hole

So in the vid from just above - he uses a METAL PUNCH tool

TO rework this panel from the TO-220 hole...

to this...

You need a punch to make a hole with no shards,

but not many are willing to "punch" the hole in a fully populated

board that uses SMD - can't be careful enough.

I guess when you look at this as a "regulator" remember the Regulator is trying to limit voltage - but supply a level of current so the "linear" in the regulation part is supposed to supply all the power that is needed - at that voltage.

The AM Regulator is unable to be a Constant Current Source unless you have the Genie in the Bottle. Right now, that's not possible - even with MOSFET designs - in regard to efficiency.

The "Siemens" factor proves that you cannot make the Bipolar a true constant current source because of the limits within the intrinsic layers - the junctions themselves.

MOSFET pulls power and abuses those stats - and is why some more popular amps that use Bipolar for their stages, pop their "pills" due to the ability of the MOSFET to be more efficient in showing low-Siemens (mho factor) at any point of is D-2-S linear slope - and gobbles up the current present at that voltage - readily. which shoves considerable amounts of power from wildly swinging output of a limter-less radio into the amp.

A TO-220 will "starve" and lose in the battle, but to control the losses you'll need a part that places more current within the traces feeing these. A TIP36C (or any selected 25A rated) in a TO-247 package. Leaving the TIP36 (recommended) in a bad position of having to supply more current at that voltage - than the Bipolar TO-220 ever could.

But while I got you here,

Your part you're putting in,

requires a rework that DOES violate a Warranty....

The TO-247 needs a hole

So in the vid from just above - he uses a METAL PUNCH tool

TO rework this panel from the TO-220 hole...

to this...

You need a punch to make a hole with no shards,

but not many are willing to "punch" the hole in a fully populated

board that uses SMD - can't be careful enough.

No, I'm certain you explained it VERY well! It's this old, not-a-technician brain that is failing. I grasp most of what you're saying about how it works, or doesn't work, and I have no intentions of making the "upgrade". I was just questioning whether or not it was worth the effort. To this, my response is a firm NO.er, no - sigh I didn't do this well enough...

I guess when you look at this as a "regulator" remember the Regulator is trying to limit voltage - but supply a level of current so the "linear" in the regulation part is supposed to supply all the power that is needed - at that voltage.

The AM Regulator is unable to be a Constant Current Source unless you have the Genie in the Bottle. Right now, that's not possible - even with MOSFET designs - in regard to efficiency.

The "Siemens" factor proves that you cannot make the Bipolar a true constant current source because of the limits within the intrinsic layers - the junctions themselves.

MOSFET pulls power and abuses those stats - and is why some more popular amps that use Bipolar for their stages, pop their "pills" due to the ability of the MOSFET to be more efficient in showing low-Siemens (mho factor) at any point of is D-2-S linear slope - and gobbles up the current present at that voltage - readily. which shoves considerable amounts of power from wildly swinging output of a limter-less radio into the amp.

A TO-220 will "starve" and lose in the battle, but to control the losses you'll need a part that places more current within the traces feeing these. A TIP36C (or any selected 25A rated) in a TO-247 package. Leaving the TIP36 (recommended) in a bad position of having to supply more current at that voltage - than the Bipolar TO-220 ever could.

But while I got you here,

View attachment 56932

Your part you're putting in,

requires a rework that DOES violate a Warranty....

The TO-247 needs a hole

So in the vid from just above - he uses a METAL PUNCH tool

View attachment 56933

TO rework this panel from the TO-220 hole...

View attachment 56936

to this...

View attachment 56935

You need a punch to make a hole with no shards,

but not many are willing to "punch" the hole in a fully populated

board that uses SMD - can't be careful enough.

I had a chance to jaw for about 3 hours last night with a buddy, testing out the Stryker. I pushed it harder than I needed to by keeping the modulation up and running a 15 watt carrier on AM. I wanted to check out hot spots, etc. I boosted the idle voltage to 14.4V and, and to my surprise, under TX the internal volt meter stayed at 13.8 to 13.9V. The best part, no heat. The left side of the radio and the heatsink, both were just barely warm to the touch, and even when I got windy kept a slightly warmer than ambient temp. So far, it looks like the Stryker is a quality piece.