Att meaning attenuator? The 7db is starting to make sense.Maybe this is the part that is disconnected. ATT 1 7dB. If so then I'll do more digging to work out what it looks like when it is properly connected.

View attachment 62414

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

-

You can now help support WorldwideDX when you shop on Amazon at no additional cost to you! Simply follow this Shop on Amazon link first and a portion of any purchase is sent to WorldwideDX to help with site costs.

-

The Retevis Holidays giveaway winner has been selected! Check Here to see who won!

Surgeon needed for RM Italy KL503HD

- Thread starter TimmyTheTorch

- Start date

All of your input power runs though it, even in the high position so it has to be able to handle ~35W without getting destroyed. It attenuates your input by 7dB.Maybe this is the part that is disconnected. ATT 1 7dB. If so then I'll do more digging to work out what it looks like when it is properly connected.

View attachment 62414

Attachments

I think the Q5n2 will be ok with the driver bypassed, maybe someone who has done the modification can verify.

@TimmyTheTorch

Here is some 503HD info you might find helpful. Ask some of these posters. This should get you started.

What amp for Galaxy 2547

I am looking for an amp in the 100-150 watt range to use with a Galaxy 2547. I'm looking at an rm Italy kl503 or a kl503 hd, I'm not sure the 503 can handle the peak swing on am, but the hd one should be able to. Any thoughts on these 2 amps or others that will fill the bill?

Rm Italy KL-503 watts vs amps

And all that for maybe 1/2 of an S unit increase over the kl203. (This is to the comment. Not the contributor). Fixed or mobile? If mobile, an all-metal or a composite-body Class 8 tractor? There came a point with radio install changes that, on AM-19 skip, if I could hear them, they could...

Rm Italy KL-503 watts vs amps

Some notes from last spring; Optima @ 10 PEP SSB | 3.8 amps | Dummy Load | Power Supply at 13.8v MFJ-826B Meter, Megawatt 36s P/S KL-503 Variable | Amperage Draw| Output Setting 6 | 32.5 amps | 200 watts Setting 5 | 30.6 amps | 192 watts Setting 4 | 30 amps | 185 watts Setting 3 | 28 amps | 160...

Rm Italy KL-503 watts vs amps

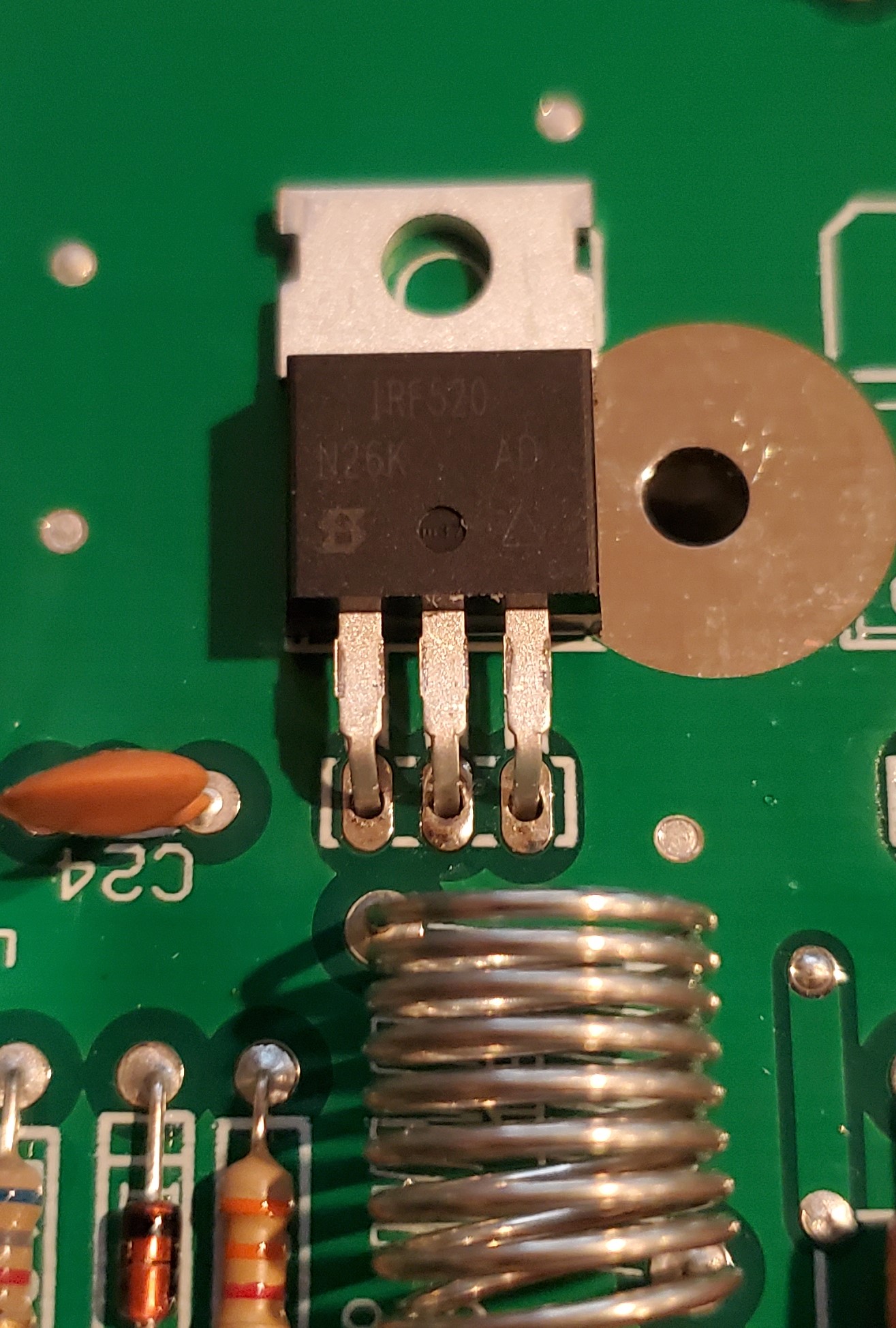

1 irf520 driving 8??? Seriously? Seems pretty stupid. May as well just be a straight 8. It would be much more versatile. Though, I suppose it would be hard to blow the final stage in that unit. I suspect the driver gets pretty stinking hot though. CbRadiosPRONTO Yes it is...

RM Italy KL 503 Crunchy

You get what you pay for. Rm italy, c'mon now, really. Well, that's a given. We all realize that. BUT my buddy is, shall we say, quite lacking in the coinage department? He's on the back side of 70 and post stroke, needs something to stay busy, and decent amplifiers today are nearly...

RM Italy KL 503 Crunchy

You get what you pay for. Rm italy, c'mon now, really. Well, that's a given. We all realize that. BUT my buddy is, shall we say, quite lacking in the coinage department? He's on the back side of 70 and post stroke, needs something to stay busy, and decent amplifiers today are nearly...

RM Italy KL 503 Crunchy

No...thank us ... NZ8N and many others contributed... To help answer the question regarding the inputs... The "realm" of CB is a money maker and a stigma - for those that wish to dive into the market of such things. If you make an amp purposely for 11 meter - you're gonna' get an X sprayed...

RM Italy KL 503 Crunchy

Update: I want to extend my gratitude to Tokin, a world class gentleman who is an asset to this hobby. With his assistance, my old pal who is post-stroke is now again able to chat with his brother on the air. Unfortunately, my friend is tech illitterate so he cant post this himself. Thank you...

Good Luck!

P.S. if you are going to bypass the driver, don't Snip things. Unsolder and lift/remove. You already have the C.B. removed from the amp.

Thank you for the PDF. It's very helpful.All of your input power runs though it, even in the high position so it has to be able to handle ~35W without getting destroyed. It attenuates your input by 7dB.

I sure must like making things more difficult for myself.

Last edited:

The replacement mosfets arrived today. Time to install them.

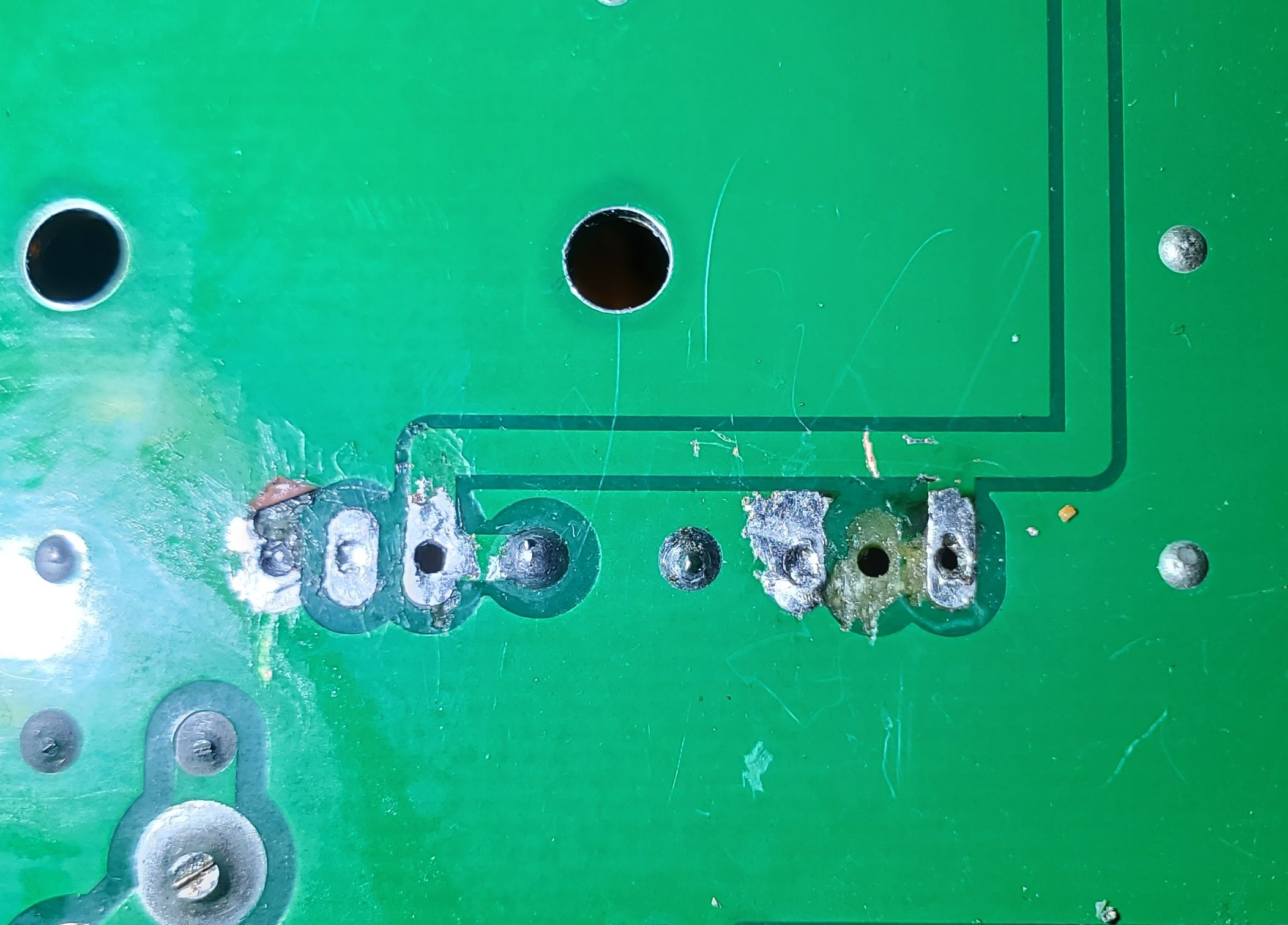

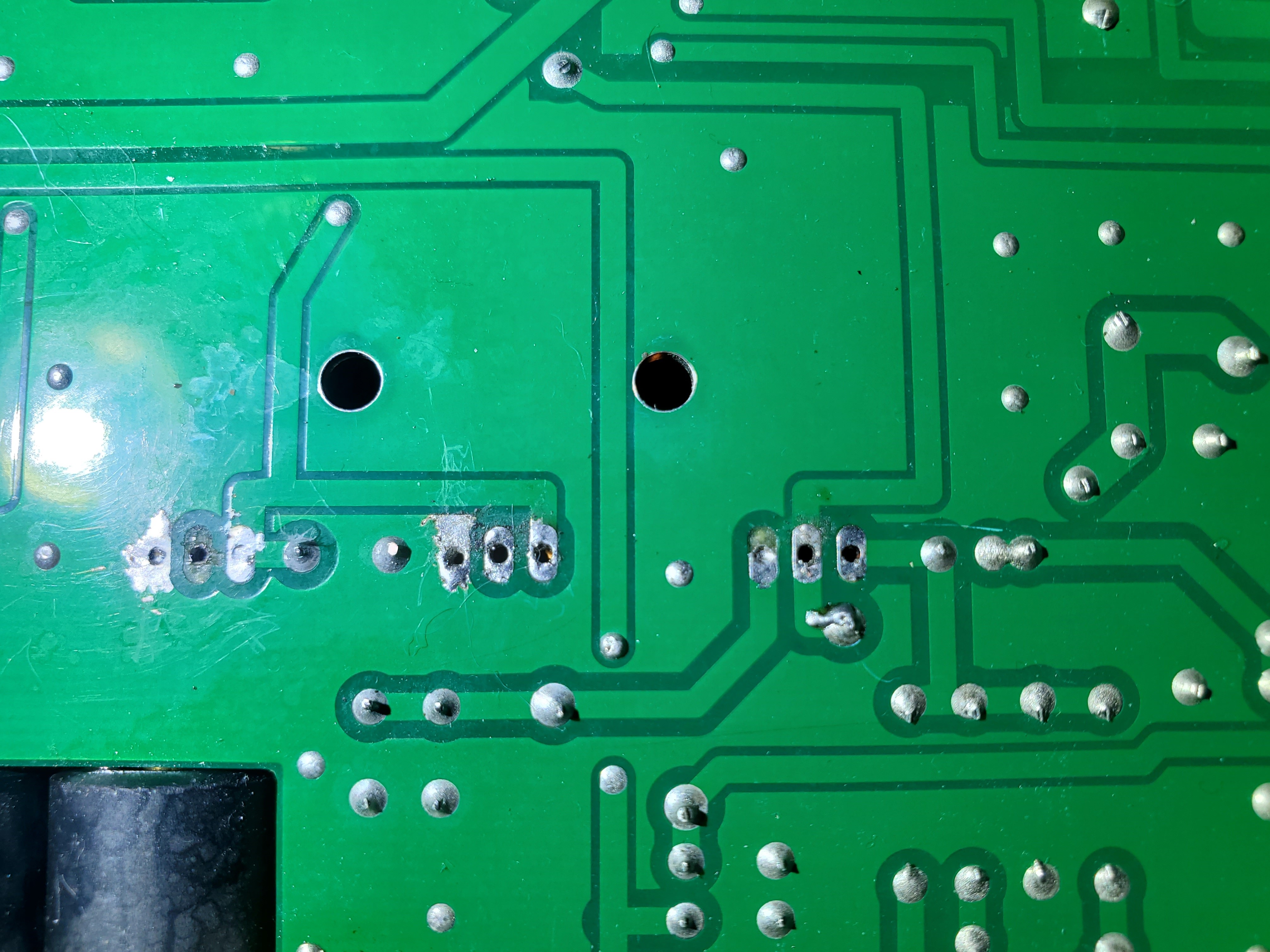

When soldering in the new ones, is it better to solder from the top side of the board or the bottom side? The top side has a lot of stuff in the way of reaching where the leg goes through the board. The bottom side has better access to the three legs. I know there will be some excess leg material I will have to trim regardless. My current plan is to solder from the bottom side as shown in the second picture.

When soldering in the new ones, is it better to solder from the top side of the board or the bottom side? The top side has a lot of stuff in the way of reaching where the leg goes through the board. The bottom side has better access to the three legs. I know there will be some excess leg material I will have to trim regardless. My current plan is to solder from the bottom side as shown in the second picture.

You'd be best from the bottom so you can trim the what sticks out too far. For assurance, I like to see the solder flow all the way through to the other side.The replacement mosfets arrived today. Time to install them.

When soldering in the new ones, is it better to solder from the top side of the board or the bottom side? The top side has a lot of stuff in the way of reaching where the leg goes through the board. The bottom side has better access to the three legs. I know there will be some excess leg material I will have to trim regardless. My current plan is to solder from the bottom side as shown in the second picture.

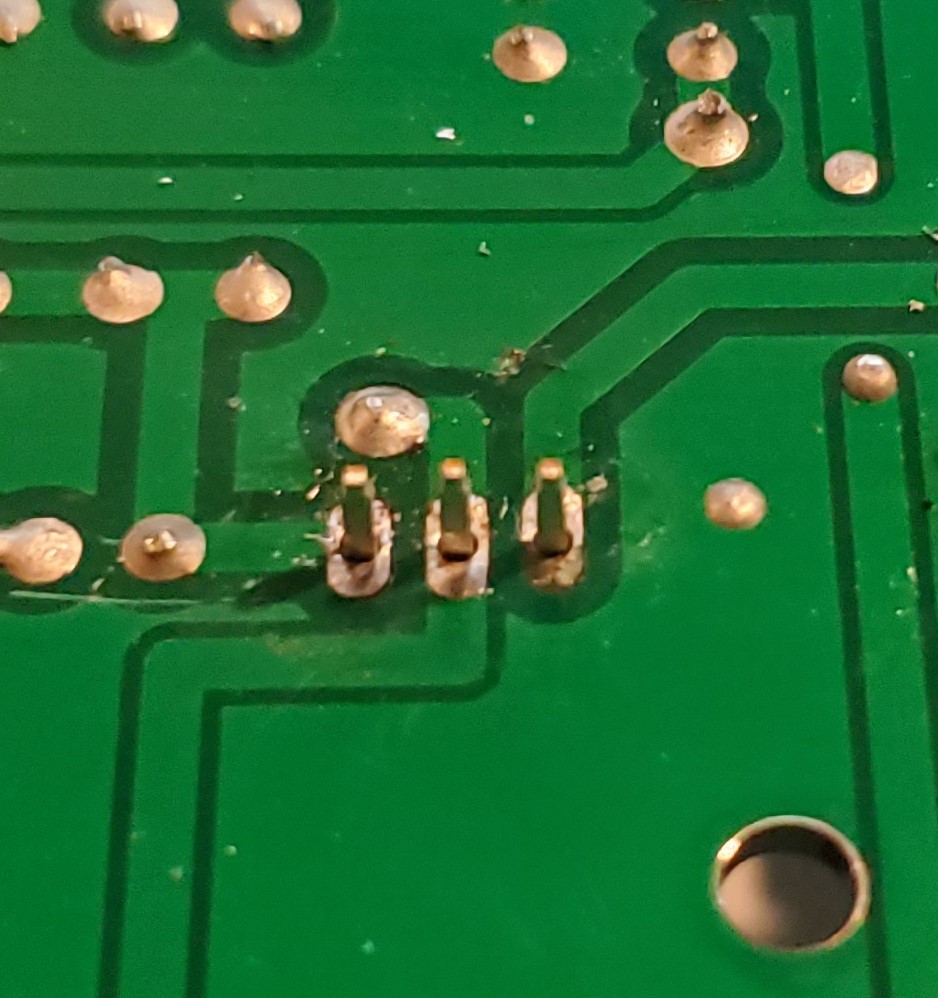

View attachment 62445View attachment 62446

I definitely need more practice soldering. I am currently finding it next to impossible with my current technique and skill level to get all of the old solder out of the three holes the mosfet legs feed through. I've been using a solder wick and solder sucker in the attempts but no joy. I even did the "add solder to remove solder" approach too but no. I then decided to deal with it when inserting the new mosfets. I just hope I did not bleep up any traces on the board whilst trying to remove the excess solder. If I did, well, that's a lesson learned.

That no lead solder is a pain. Add a little flux, some fresh solder and repeat as needed.

What type of iron are you using?

What type of iron are you using?

The replacement mosfets arrived today. Time to install them.

When soldering in the new ones, is it better to solder from the top side of the board or the bottom side? The top side has a lot of stuff in the way of reaching where the leg goes through the board. The bottom side has better access to the three legs. I know there will be some excess leg material I will have to trim regardless. My current plan is to solder from the bottom side as shown in the second picture.

View attachment 62445View attachment 62446

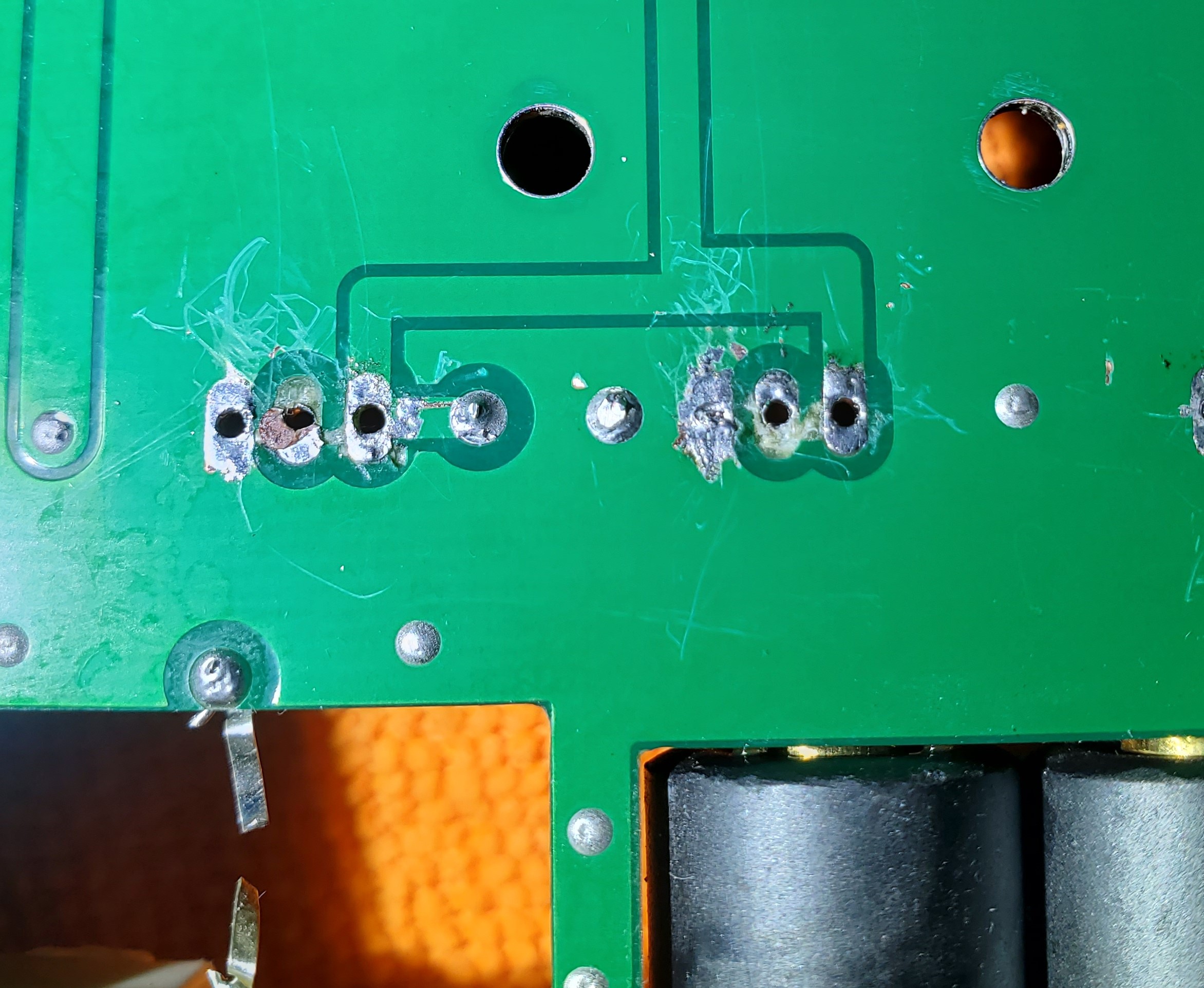

Please tell me this is NOT how you soldered in the replacements...

If so, STOP! DO NOT TURN ON THE AMP.

The Mosfets are backwards. They should be soldered on the UNDERSIDE of the circuit board - just like they came out.

The Mosfet "tab" is what goes down against the "thermal pads" on the aluminum heatsink. The legs stick UP through the 3 holes. No thermal grease is needed on the Mosfets.

I highly recommend using flux cored eutectic solder. Kester 44 has a 3.3% type 44 flux core and the flux is "active". It may leave a slight non-conductive "residue". IMHO, this is the best all around solder. For oxidized solder or copper, the 44 flux has superior wetting. The residue, if any, can be cleaned with alcohol.

Amazon product ASIN B0149K4JTY

You can also use a "no clean" type of flux cored eutectic solder that has a 1.1% type 245 flux that leaves no residue. It has a "mildly active" flux. This will work fine on any non oxidized connection.

Amazon product ASIN B00068IJOU

Spare your self the angst, frustration, burned up traces, and transistors and DON'T use a NO Lead solder.

P.S. Also, you didn't mention if you are going to bypass the driver or not. If not, then the 7dB part is correct.

If you are going to bypass the driver then the 7dB part is not correct. You would use a 3dB 40w part.

Attachments

Last edited:

No soldering has been done yet. Seems we have some new folks in our support area that are not quite up-to-speed on how to handle after-hours production outage alerts. Fun evening!Please tell me this is NOT how you soldered in the replacements...

If so, STOP! DO NOT TURN ON THE AMP.

The Mosfets are backwards. They should be soldered on the UNDERSIDE of the circuit board - just like they came out.

The Mosfet "tab" is what goes down against the "thermal pads" on the aluminum heatsink. The legs stick UP through the 3 holes. No thermal grease is needed on the Mosfets.

This is the Kester 44 solder I got the other day when I also got the recommended solder sucker.

For now I decided not to bypass the driver. I decided if I bypass the driver at the same time as I replace the mosfets (especially with being a newbie at this stuff), I would have less idea on what was wrong in the event it did not work properly. The 7 dB attenuator was ordered on Monday, not sure yet when it will arrive.

I won't be using my Anytone AT-5555N II with this amp when I am done so it should have a safer life.

And thank you again for all of the information. I am glad you do not assume that I will do the stuff correctly. I did take some pictures of the innards before I started but missed some areas.

I got up this morning to find a note on the dishwasher that it won't run and a plugged sink in my youngest daughter's bathroom. Long hair and makeup products do wonders for a teenage girl's living environment. Beats being bored!

I definitely need more practice soldering. I am currently finding it next to impossible with my current technique and skill level to get all of the old solder out of the three holes the mosfet legs feed through. I've been using a solder wick and solder sucker in the attempts but no joy. I even did the "add solder to remove solder" approach too but no. I then decided to deal with it when inserting the new mosfets. I just hope I did not bleep up any traces on the board whilst trying to remove the excess solder. If I did, well, that's a lesson learned.

Using the solder sucker I mentioned earlier.

The trick is to use a conical or small chisel soldering iron tip (minimum 700F) and come in at a 10~20 degree angle from horizontal and once the solder turns to liquid (less than 1 sec), LEAVE it there.

Then with your other hand place the solder sucker straight down on the through hole and the soldering iron tip. The Silicone tubing will form an airtight seal around the tip and the PCB surface and then push the button (1 sec).

Total time = <2 seconds and you won't burn up the trace or damage the component.

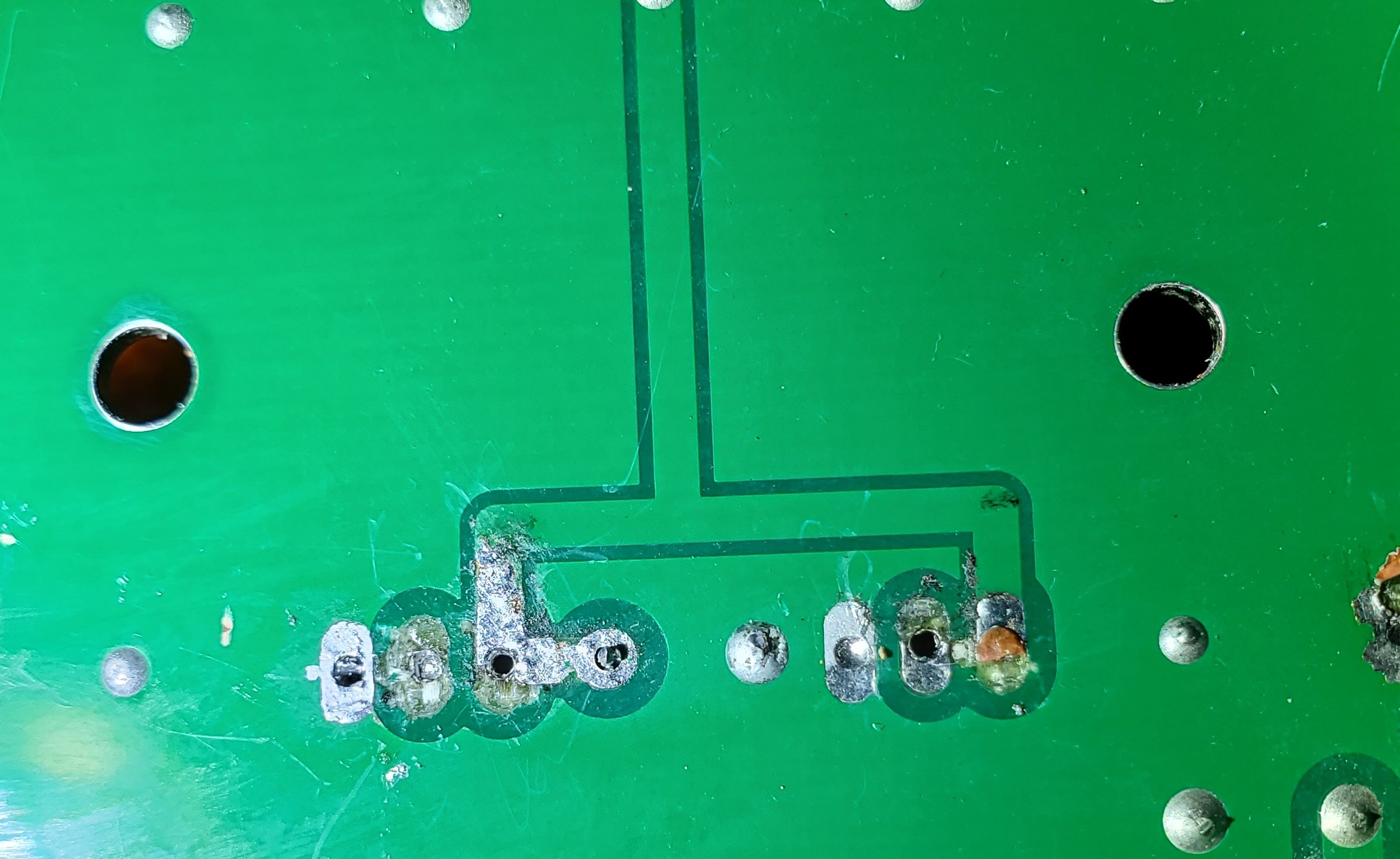

I spent a lot of time jacking around with a pointed tip that I think I bleeped up a few of the pads. By the time I changed to a chisel tip and learned the "add solder to remove solder" tip, I was nearly done. The surface scratches are from my first attempt at pulling the mosfets when using the pointed tip to melt the solder. FAIL. If I killed the board, so be it. I've learned a lot from the folks here during the short time I've been a member and learned a lot about what not to do. A few lessons may prove more costly than others. I even bent my wife's favorite tweezers. That's not good! But, onward and upward.

My Dad spent nearly 50 hard years as a sheet metal / iron worker and I sure could have used him around again for the 1000th time since he passed. First he'd have busted my balls for what I did with such a tiny soldering iron, then he'd grab us a few cold ones and the teaching would start.

After the cleanup here's what I am left with. I doubt I'll be able to work on this again until Monday night. Who knows, this may end up posted as an amp for parts listing but I really do hope I can fix my own bleep-ups and get this working again. I am a proud member of the "Tubthumper Society"... I may get knocked down but I get up again. Also a good approach when growing up playing hockey for 25 years or so.

Maybe this should be a sticky with a "Cautionary Tale" tag.

My Dad spent nearly 50 hard years as a sheet metal / iron worker and I sure could have used him around again for the 1000th time since he passed. First he'd have busted my balls for what I did with such a tiny soldering iron, then he'd grab us a few cold ones and the teaching would start.

After the cleanup here's what I am left with. I doubt I'll be able to work on this again until Monday night. Who knows, this may end up posted as an amp for parts listing but I really do hope I can fix my own bleep-ups and get this working again. I am a proud member of the "Tubthumper Society"... I may get knocked down but I get up again. Also a good approach when growing up playing hockey for 25 years or so.

Maybe this should be a sticky with a "Cautionary Tale" tag.

A learning experience but not all hope is lost there my friend. See those pads you pulled off, they can still be flowed from the other side with a little patience. No it won't be pretty but can still work. Pads that need to be soldered on the side you're showing us still have enough foil to flow onto.I spent a lot of time jacking around with a pointed tip that I think I bleeped up a few of the pads. By the time I changed to a chisel tip and learned the "add solder to remove solder" tip, I was nearly done. The surface scratches are from my first attempt at pulling the mosfets when using the pointed tip to melt the solder. FAIL. If I killed the board, so be it. I've learned a lot from the folks here during the short time I've been a member and learned a lot about what not to do. A few lessons may prove more costly than others. I even bent my wife's favorite tweezers. That's not good! But, onward and upward.

My Dad spent nearly 50 hard years as a sheet metal / iron worker and I sure could have used him around again for the 1000th time since he passed. First he'd have busted my balls for what I did with such a tiny soldering iron, then he'd grab us a few cold ones and the teaching would start.

After the cleanup here's what I am left with. I doubt I'll be able to work on this again until Monday night. Who knows, this may end up posted as an amp for parts listing but I really do hope I can fix my own bleep-ups and get this working again. I am a proud member of the "Tubthumper Society"... I may get knocked down but I get up again. Also a good approach when growing up playing hockey for 25 years or so.

Maybe this should be a sticky with a "Cautionary Tale" tag.

View attachment 62476

View attachment 62481

View attachment 62482

View attachment 62483

View attachment 62484

Just a thought.

dxChat

- No one is chatting at the moment.

-

@ BJ radionut:

HEATHKIT SB220 Used [.20462] - $999.00 : R&L Electronics, Amateur radio store

R&L Electronics HEATHKIT SB220 Used [.20462] - HEATHKIT SB220 MODIFIED TO ONLY WORK ON 6 METERS TESTED, HEAVILY MODIFIEDwww2.randl.com -

-

-

@ benc48:Need help lost my channel chart . Cobra 148 GTL with a 8719 and 11,1125 crystal 26.175 to 28.045 , Need the chart I can fill in the blanks slide 2ck up and 12 kc down

-