You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

-

You can now help support WorldwideDX when you shop on Amazon at no additional cost to you! Simply follow this Shop on Amazon link first and a portion of any purchase is sent to WorldwideDX to help with site costs.

-

A Winner has been selected for the 2025 Radioddity Cyber Monday giveaway! Click Here to see who won!

Sirio 2016

- Thread starter GaRebel

- Start date

huh brads? id think they be loose in wind n open holes upInsteard of using the little screws, using a brad would this work just as good?

Grade 316 (not 304) Stainless Steel Hose Clamps and apply a thin layer of Liquid Tape on the clamps and at the joints.no ..use hose clips ..good quilty preferably stainless and cover with good quality electrical tape

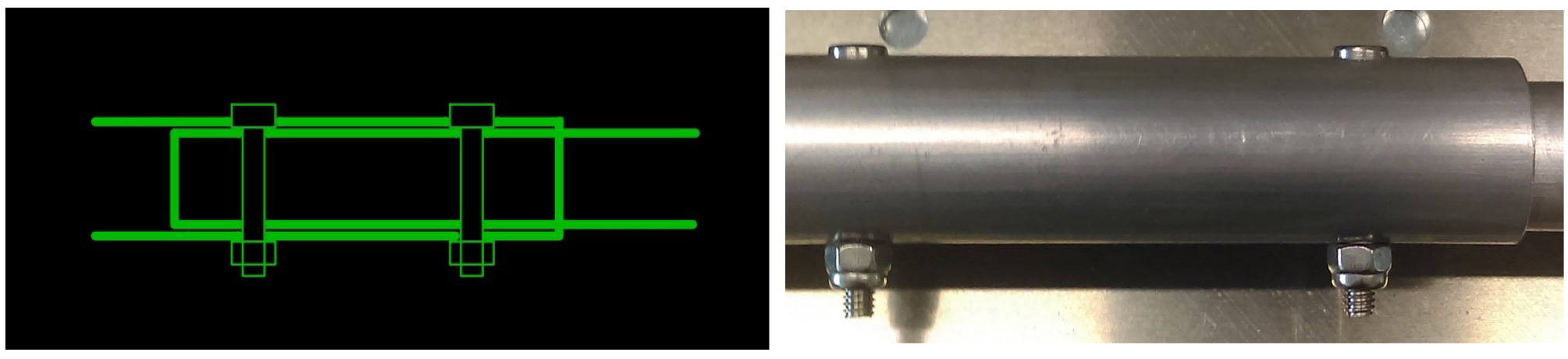

That's the way to do it. Inox locknuts and screws.

i cut and past this from a reply i did on FB yesterday ..looks like good electrical tape applied well can last 35 years.. i never had any problems with any joint i have ever done unless there was a mechanical fail

>>>>to seal joints i use just good quality electrical tape..i make certain i keep it tight and slightly stretched when rapping it ..i have remains of a 5/8th wave i made when i was 18 laid down outside at the back of a shed on the floor and all the roof water falls on it as no gutter..the other year i was short of a jubilee clip and remembered the old antenna i cut the tape and the clip was relatively rust free would have been second hand as all the ally on the antenna was and the joint was pretty good with any corrosion looking like moister had got in from the inside of the antenna..probably as lade on its side ..it was probably about 35 years old .... i have not had as good look with self-amalgamating tape i used quality 3M self-amalgamating tape on my Sirio V4K ,, I take it down to repair the basket after about 18 months i find that the tape had stuck to its self very well but not so well to the aluminum exspaily around tight radiuses and their was sighns of water ingres and slight corrishion under it ,, i remuved it all and relaced it with good quality electrcal tape......... bugger the spell cheker has stoped

>>>>to seal joints i use just good quality electrical tape..i make certain i keep it tight and slightly stretched when rapping it ..i have remains of a 5/8th wave i made when i was 18 laid down outside at the back of a shed on the floor and all the roof water falls on it as no gutter..the other year i was short of a jubilee clip and remembered the old antenna i cut the tape and the clip was relatively rust free would have been second hand as all the ally on the antenna was and the joint was pretty good with any corrosion looking like moister had got in from the inside of the antenna..probably as lade on its side ..it was probably about 35 years old .... i have not had as good look with self-amalgamating tape i used quality 3M self-amalgamating tape on my Sirio V4K ,, I take it down to repair the basket after about 18 months i find that the tape had stuck to its self very well but not so well to the aluminum exspaily around tight radiuses and their was sighns of water ingres and slight corrishion under it ,, i remuved it all and relaced it with good quality electrcal tape......... bugger the spell cheker has stoped

Yes, but there could be a problem compressing against the hollow pipes / radials. If there was a solid piece of aluminum inside the smaller diameter radial, the fasteners would have something to tighten against.That's the way to do it. Inox locknuts and screws.

View attachment 60776

My Sirio 2016 has been up for 16 months now. I used Ox-Gard on the sections, and used blue Loctite on the screws. It's still working great!

That's great! My concern would be if the fasteners were too tight, the radials would collapse and be oval shaped which would leave a path for water and moisture to enter the joint.I did that in a few antennas with 1mm walls. No issues. Antennas over 10 years on tower. Still in one piece.

Sorry, I was thinking rivets.Use rivets and a conductive paste between sections....

Brads are nails for wood...

Using rivets would definitely compress the hollow radials and you would have a mess. Using hose clamps is effective because they apply pressure on the entire circumference of the male to female connection, whereas using screws or thru-bolts only apply pressure under the head of the screw and/or under the head of the bolt and under the nut. The majority of the female ends on two-piece radials have two or more splits and provide a friction-fit between the male and female surfaces which will "almost" produce a watertight seal. Hose clamps with a layer of tape, sealant, Liquid Tape, etc. etc., covering the clamps, splits and the minute gap at the joint, will last for a long time.Sorry, I was thinking rivets.

i second this way. works every time for me alsoThat's the way to do it. Inox locknuts and screws.

View attachment 60776

Greg T

WDX-945 (Jazz Singer) Upper Peninsula of Michigan

dxChat

- No one is chatting at the moment.

-

dxBot:brandon7861 has left the room.

-

-

-

-

@ boniface95:Hi there, I just posted this question, if anyone has time to check it out, i'd really appreciate some feedback. https://www.worldwidedx.com/threads...-radio-transmitters-in-the-same-space.270736/