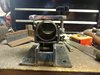

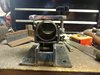

More progress. This is the top clamp. I made the brackets strong enough to drive a truck over them because I don't want them to be the weak link. The idea is to be able to tilt the mast up and down without tools. Found a knob in my junk drawer. The bolt head jams nicely against the weld for the big nut that it goes through. This loose fit for the bolt allows it to move slightly to the side as the hinge plate swings into position. I will put a zip tie around the bolt to capture it so I don't loose it.

Last edited: